I use two sided jigs that I have made to make my track curves as smooth and consistent as possible.The jigs are made from 1/2" MDF. Each jig has two radii for each curve radius that I will need. Those radii are 72", 80", 88", 96", 104", 112", 120". AS an Example for O-96" I made the top of the jig radius 46 15/16" and the bottom radius 49 1/16". They are 48" long, and close to 4" wide. The lessor radius is always on the top and the greater on the bottom. This arrangement allows me to bring the ties in contact with the jig from the outside, or the inside of the curve. The track ties can be brought into contact with bar grip clamps and fastened down as you proceed.

Jig Radii Top (inside) Bottom (Outside)

72" 34 15/16" 37 1/16"

80" 38 15/16" 41 1/16"

88" 42 15/16" 45 1/16"

96" 46 15/16" 49 1/16"

104" 50 15/16" 53 1/16"

112" 54 15/16" 57 1/16"

120" 58 15/16" 61 1/16"

The radius can be cut by following the circumference tool's drawn line as shown. Or if available use a Festool jig saw with the special curve cutting attachment.

If I am laying parallel tracks. I use an addition jig that will allow the appropriate inter-track clearance. Or, I use multiple, equal sized blocks, (6 to 8) every 3 or 4 ties off the original installed curve. This option allows easy installing of curves that are not the standard size radii. instead of 96" you might need 94 1/2" radius, which would require a set of 2 5/8" blocks between the 104" radius ties and the desired 94 1/2" radius curve vs the 1 7/8" for the 96"radius curve.

Group of Jigs

80" 88" 96" 104" 112" 120" and 72" (Not Shown)

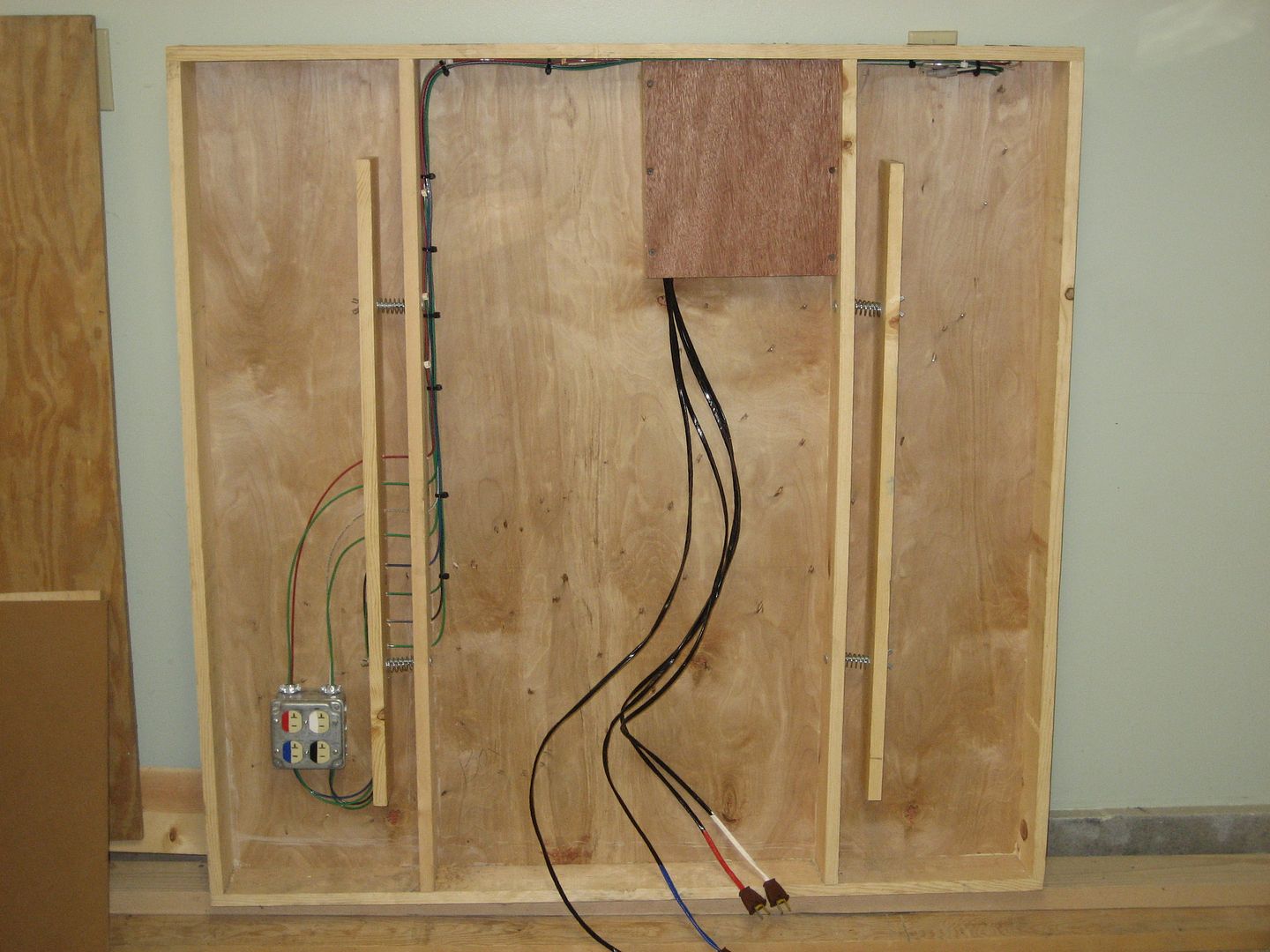

The start of the Double Main Curve

Base for Double Main Curve

Final Check of main.

That it is consistent, straight, and equal distance from edge

Jig Use

The jig is screwed down on both ends

Clamping

Clamping makes mating of new section easy and smooth.

Mated Sections

I usually have to tap the far end on individual rails to get them tight and a smooth curvature.

Outside Main Completed

Starting Inside Main

Jig placed and assisted by clamping

Setting Inside Jig

Alternative method is to use a multiple blocks against the first set curve.

This works very well if you want a non conventional radius size like 86" or a 74" radius.

Completed Inside Main Curve

The Real Test

Do I have enough clearance between the Big Boy and The Allegheny and Lionel Auto Carrier and Atlas 21" CZ. The tightest issue I have is the Big Boy and the Lionel Auto Carrier (on the outside Track)

Do I have enough clearance between the Big Boy, The Allegheny, Lionel Auto Carrier and Atlas 21" CZ. The closest is the Big Boy and the Lionel Auto Carrier

Thanks for Looking

Buzz