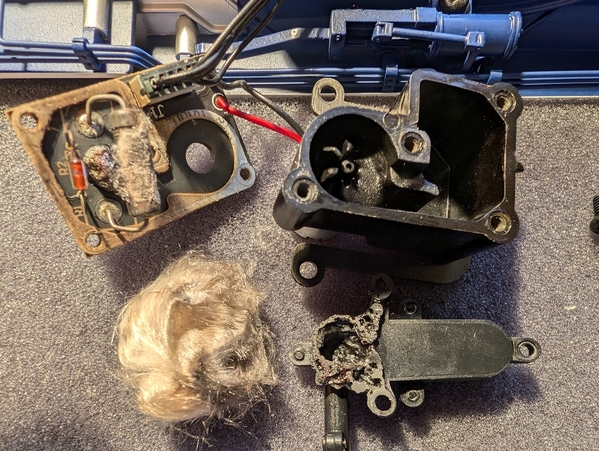

First time I've seen this. Put it on the track, and the whistle steam smoke unit was *working* but just wafting out, no fan-driven movement. After about 5 minutes I could smell plastic and immediately pulled it off the layout.

It looks like the motor itself bound and then started melting. The actual smoke element and batting seem fine. I see that the smoke unit is available from Lionel directly, but I'm not sure about the funnel assembly. There's a part called "SMOKE FUNNEL / WHISTLE SMOKE / 4-8-4" (cs-2031160-201-p) which might be what I need, but there's no picture.

Does anyone have any idea what that part number is? I'm assuming I just write the smoke unit off as a random loss, I didn't see any issues with the wiring, and the heating element worked just fine. Anything I should watch out for?