someone posted on how to construct a corn bin using brass screen wire.

Replies sorted oldest to newest

I don't remember seeing it here, but page 53 of the Feb/Mar 2015 (#276) current issue of OGR has an article on building a corn bin.

Is a "corn bin" the same as a corn crib?

Sort of like 1 of these...

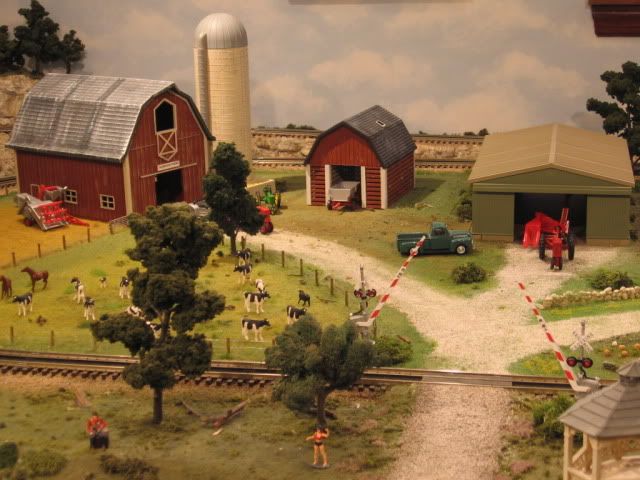

Great Martin ![]() Mentioned in this thread. We had talked about this quite a while ago. The design pictured, has two storage area, left and right of the access door. Ear corn, even mature, and field ready for harvest, still has a relatively high moisture level. The crib design, allows for air dry of the corn ears, with out mold, and lost of product. Air under the crib was also very important. Hardware cloth/wire mesh was installed on the inside of the boards pictured, to hold the corn ears in place, and still allow maximum air dry effect. Usually the air dry crib worked best if the corn bin was 4 ft or less in width. As the cribbed corn dried over the winter, it would shrink as much as 1/4 to 1/3 by volume. Here is another drive-thru crib from an Ertl farm set, picture center.

Mentioned in this thread. We had talked about this quite a while ago. The design pictured, has two storage area, left and right of the access door. Ear corn, even mature, and field ready for harvest, still has a relatively high moisture level. The crib design, allows for air dry of the corn ears, with out mold, and lost of product. Air under the crib was also very important. Hardware cloth/wire mesh was installed on the inside of the boards pictured, to hold the corn ears in place, and still allow maximum air dry effect. Usually the air dry crib worked best if the corn bin was 4 ft or less in width. As the cribbed corn dried over the winter, it would shrink as much as 1/4 to 1/3 by volume. Here is another drive-thru crib from an Ertl farm set, picture center.

IMO and excellent scratch build project for just about anyone IMO

Great crib model mwb.

Our corn crib at the Farm was log-built about 1905 and the space between the logs was left open for ventilation. There was an wide open space under the eaves where we could unload ears by standing on the wagon and pitching them in the crib.

We had cats and Grandpa's big blacksnake that controlled the rodent population. We merely shot the invading crows. It was not unusual to touch the snake at night while standing at the door, holding a lantern in one hand and loading ears in a bucket to feed the mules/horses/hogs. I think he laid around close to the door waiting just to scare me![]() .

.

Usually around October we would have a corn shucking and take a majority of the ears to the Mill for grinding into an animal feed mixture and of course kitchen corn meal.

Plasticville made a nice one.

Thanks for the information, I didn't remmber I had seen it in the magazine.