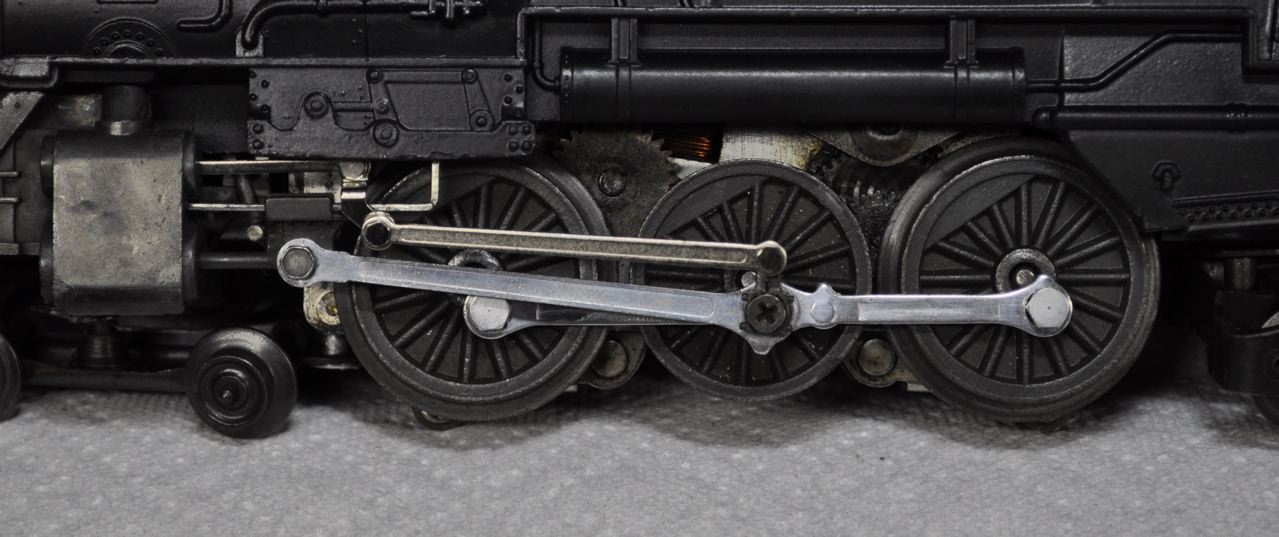

Yes, these are postwar and they are all consistent from where I got them from, its like they where all stored the same and have the same yellow on their metals. I have seen it before but never acquired any with it. Non of my own collection has this.

I am afraid to use anything abrasive as that is a pet peeve I have. I will start with soap and water and go from there.

That discoloration is common. According to my understanding it is oxidation, but I cannot find anything much in the way of a direct reference. It might be Chromium (III) Oxide or Nickel(II) Oxide

According to Wikipedia, if it is Chromium (III) Oxide, it would take more than soap and water to get rid of it.

Same goes for Nickel (II) Oxide.

The first couple of times I ran into Lionel pieces with that discoloration, I did try to clean it off, without much success. Plus, if it is Nickel (II) Oxide, Wikipedia says its nasty stuff to inhale. These days. I just consider it part of the patina.