Been slowly working on a 1950 773 a friend gave me. I did the Dennis Waldron service and tightening on the gearbox, etc. Bought a new boiler front from him a couple years before his passing, but never thought to buy one of the Gold Seal High Stack motors he offered. After reading all the info here, I had to have one, but he was gone by then. Heard that Trainz had bought his stock and kept bothering them for one of those motors. Finally, a few months ago they listed a 773-200 high stackk motor on eBay and I ordered it.

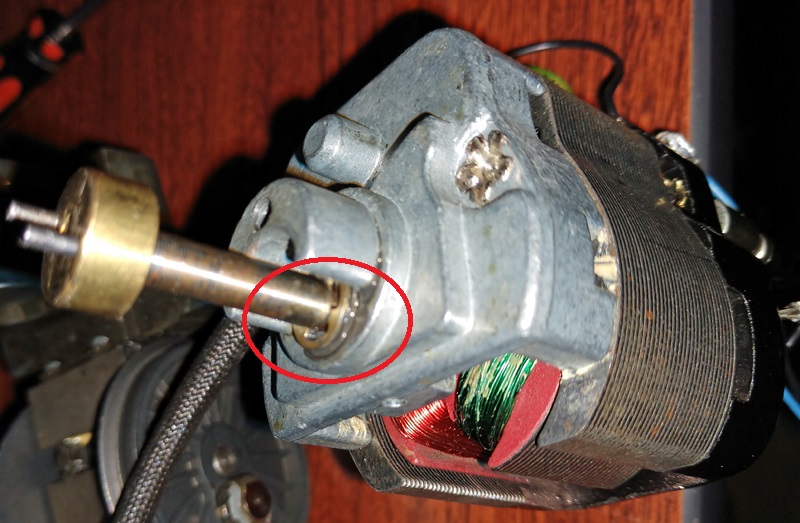

Yesterday I finally had time to play and decided to check how it ran before all the soldering. Not mounted, no E-unit, just the bare motor with alligator clip jumpers from one of my ZW's. It runs fine in one direction but only hums hooked up the other way. Reattached 3 times each direction, same results every time. Armature spins easily by hand in both directions, but turniing it with power on in the direction it doesn't want to run shows no difference.

I contacted Trainz and they have no more to exchange, so it's mine all mine to repair.

Brushes seem fine, no obvious electrical or mechanical issues visible without unsoldering and taking off the brush plate. I do notice that the motor was obviouslly installed somewhere before, because there was once a wire soldered to the right motor screw lug - opposite the left one where one field wire is soldered.

I don't know what resistances are typical for the field or across the back of the brushes, but no big changes pop out at me as I spin the motor and watch the readings.

Anything else to check before I go further?

Thanks!

Karl