I recently bought this Overland Models brass loco and it crawls really well for switching using a GML throttle. This is my first brass OMI loco and I really don’t know much about the mechanical drives in these engines. However, the transmission seems a bit noisy, which is clearly audible in the attached video. The noise is inaudible at a crawl, but gets more pronounced as it picks up speed, occurs in both directions (altho slightly worse in reverse). Any thoughts as to whether this is normal, something to worry about, how to fix, etc, would be much appreciated. Thanks!

Replies sorted oldest to newest

I will disconnect mechanical part one by one and test.

Move manually each component looking for movement interference.

my 2 cents.

AG.

I know that engine very well. came from Tony Ambrose estate. it has a Stu Kleinschmidt drive installed (KES) and I painted it. should be a date on bottom of box with my initials.

the noise sounds similar to what you'd hear with a chain and sprocket drive. the gearbox has gears, not chain & sprocket, so that's ruled out.

perhaps the flywheel is not balanced and is vibrating the entire drivetrain.

does the vibration frequency change with speed?

or... there is slop in the universal joint(s).

Thanks for the replies.

Bob, the box is dated 1/21/89. And what a beautiful paint job!

Chris, the vibration increases and the sound gets louder with increased speed.

I've never disassembled one of these and am reluctant as there is a note on the frame reading "do not remove transmission drive". Don't know if that was placed there just for the painting or if there is a mechanical reason not to remove the drive.

If this helps, here's a shot underneath the trucks.

Any tips on how to proceed? ...and will disassembly mess anything up??

...gregg

Attachments

Is that part on the motor output shaft suppose to wobble ?

Great looking locomotive

Clem

As has been pointed out - the drive shown is not original Overland. I believe the model was an early 80's import - back when Overland diesel drives used a poorly engineered center tower drive without flywheels. I had a set of E7's with this drive and the plastic tower gears failed within a couple of years. For many years Overland models had a poor reputation in the O scale community due to the weak drive. Gradually Overland responded to customer feedback and in the late 1980's/early 90's Overland switched to double shaft center mounted Pittman motors with flywheels on each end. Each truck had a gear tower. I have several models with this drive (Sharks, FA1's, and E8's and they are smooth quiet runners. In some cases Overland re-ran the early diesels with the improved drive. They sold drive train components and some modelers did their own upgrades. Others sent their early Overland models to custom repowering shops like Stu Kleinschmidt.

Ed Rappe

Kleinschmidt is famous for bulletproof drives. I think I would look for something really simple, like a rotating part contacting the body or part of the frame. I cannot believe it would be gear noise.

I am with Ed above - early Overland drives were designed for mantelpiece models.

The drive seems solid - slight play in one end of a shaft to a flywheel, but the flywheel is fine. I hit all obvious points with a drop of oil. All parts up top are well clear of the frame. I can't tell down below the frame - the transmission goes down below the frame and is hidden by the fuel tank.

I suppose I can remove the trucks and see if there is a rubbing problem with the driveline and U-joints.

Should I unscrew the fuel tank and drop the trucks? The trucks are held on by a screw - will they simply drop down for inspection, or is there something I need to do to disassemble the U-joint assembly?

Many thanks for the education!

Having worked on & built many drives I'm sure it would be fun to troubleshoot but, and it's a big but, why not contact Stu & have him check it out.

Jay

Yes, Stu could spot it in five minutes. Last I heard, the wait list was ten years . . .

Can you get the fuel tank off, and run the mechanism observing all rotating parts? Is it at all possible that a flywheel has lost a screw? An ever-so-slightly out of balance flywheel can make a sound just like a self-destructing gearbox. You might be able to rig up a pointer or something over each flywheel to look for slight variations on the outer diameter.

Yeah, ten years for an install. Might not be the case for a minor repair. Screw with it and make it into a major repair and it may get drawn out. You won't really know unless you ask.

Jay

Good idea - I'll go to the source. I Googled Stu Kleinschmidt and only came up with links mentioning him. Anyone have a contact?

Thanks...gregg

I'll see what I can dig up & let you know.

Jay

Thanks Jay. I located a Stewart Kleinschmidt in Illinois, with a street address and a phone number only. Don't know if it's him and there was no email or web info.

I don't usually like "high" hood units. I'll probably get blasted for saying that.

This engine is beautiful. Not quite sure if it's the proportions, or the great details?

I hope it's not just the beautiful paint job! (I'm getting old?..... really older??)

Greg,

I have the info (phone number) and I'll email it to you.

I'm sure most of us would like to know how all this plays out. If you're so inclined, please let us know.

Jay

Gregg,

I tried to send the info to you via the email address shown on this website and the message bounced.

Jay

Gregg,

I tried to send the info to you via the email address shown on this website and the message bounced.

Jay

Gregg,

I forwarded the original message to your mac.com email.

Jay

Gregg,

Any updates?

Jay

It sounds like a too tight gear mesh in the transmission. The gears may somehow have tightened against one another. Also missing a tooth on one of the gears will make that kind of sound. You can turn it on it's side or on it's roof and run it and make a stethoscope," long Philips screwdriver", and listen to the wheel transmissions and the main transmission to identify or pin point where the noise is coming from.

Good Luck,

Ron

I suppose I could have been more specific.

Gregg,

Did you get in touch with Stu? If so, any updates.

I was given a USH SP MT3 to work on that has a Kleinschmidt drive installed. It may have been tampered with by someone other than Stu after he worked his magic. I say this because the motor has a 1982 date on it and everything else is dated earlier.

At this point, I'm remotorering it because the Pittman can motor that's in it has the weak alnico magnets and the darned thing will barely pull itself (it does have additional weight added).

Jay

Gregg,

Back in November I emailed you suggestions and photos...what ever happened with your request for help?

Matt

I stupidly got three other projects underway on the bench at once and literally have no room to tackle the OMI drive. Am going to OSW in February and hope to have it diagnosed by then.

Gregg,

I'll be stationed at the Protoctaft tables and would be happy to take a look at it, if you want.

Jay

Very nice engine and look at, a sure 10. I hear your desire to correct this problem. Like all my HO brass engines had a nice whine and not the sound like the flanges running over the ties.

Hope you find a inexpensive fix to you problems. I was wondering if anyone has video of the fixes to Overland U50s from the original power trains. I have 2 that I am thinking putting up to snuff. Hate to think they stay shelf queens.

Phil

Gregg,

I'll be stationed at the Protoctaft tables and would be happy to take a look at it, if you want.

Jay

I'm no expert but the arrangement looks like drawings I've seen of a centrifugal clutch drive. If the motor is connected to the flywheel through a clutch, some noise is normal.

I've been told that these clutches are tricky to adjust. If it were my model I wouldn't take it apart. Based on the video it seems to run very well and smoothly, I don't find the noise objectionable, so I would leave well enough alone.

The latest on Gregg's beautiful RS11 is as follows. I spent quite a bit of time going through the drive and I will say it's really impressive. Having said that there were inherent issues that just could not be resolved to Gregg & my satisfaction. The problems included a noisy & weak Sagami motor (probably the original from OMI), the clutch that didn't really operate as a clutch and was noisy, the ball bearings supporting the clutch & adjacent flywheel were noisy, the tower was noisy also. Bottom line, everything made noise. Some was improved with lubrication but not nearly enough. We elected to remove the original drive intact. It could be re-installed at any time.

Gregg decided to go with the Faulhaber gear head motor, ball bearings on all the journals, wipers all around and convert the loco to P48. If he decides to go back to regular O Scale all we have to do is readjust the side frames and change axles & wheels (all of this is pretty much a drop in now).

I'll attach some photos via photobucket.

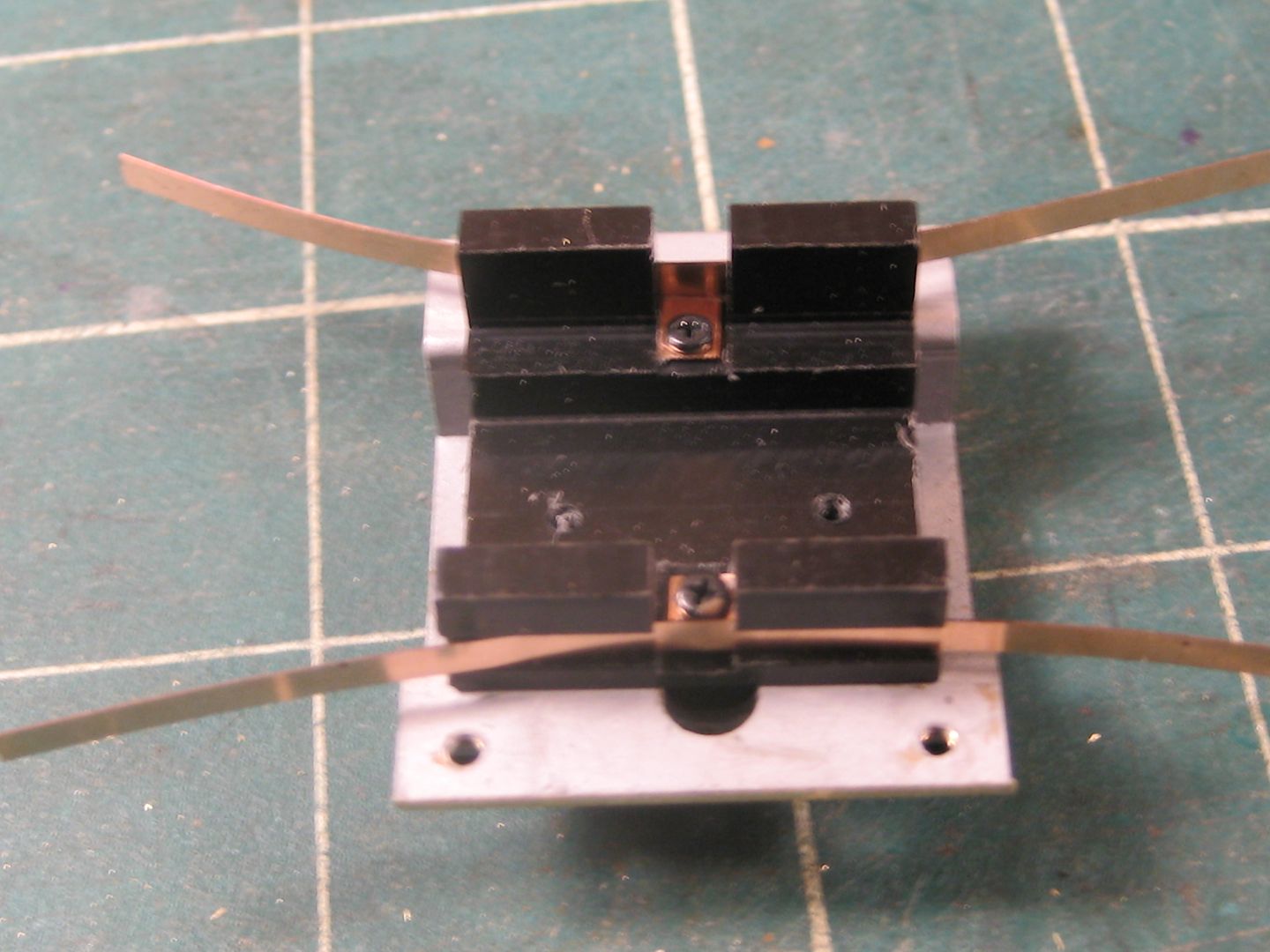

These are the only pieces of the frame & mechanism we will reuse.

Pre ball bearing installation

Notes written on the frame. I assume not all were by Stu.

Ball bearings installed and new axles been tested for fit.

New wheels & 1:1 gearboxes installed.

Preliminary installation of the gear head motor. Turns out it need to be lowered considerably so the drive shafts would be level with the frame.

Ready for wiper mounts

Beginnings of the wiper mounts

Wiper mounts & wipers installed

Waiting for the Tsunami sound decoder (supposed to be here tomorrow).

This speaker ought to provide enough sound!

One really cool thing, there were so many holes in the frame I just designed everything to fit the existing holes.

Jay

That is some really nice work!

Larry

well, so much for the cheap fix

Thanks Larry. I try to do my best.

Yeah Bob, it will probably be more than yours was. Adding DCC, sound, wipers and converting to P48 would have added to the cost anyway. Dumping the Sagami was a no brainer.

Jay

Excellent engineering in your drives Jay! That loco will be a complete joy to switch with. ![]()

Please forgive me poking my nose in, but I have a suggestion regarding the speaker. I have used this type of speaker wherever I can fit it in. I have found that it gives a warm, rich and full-bodied sound. It can get closer to the bass notes than smaller units of course, especially with a large well sealed enclosure such as you have. But I have found it lacks the crisp treble needed for a really convincing bell. So adding one of the new "sugar cube" speakers (good quality such as from Apple tablets and phones) in a suitable enclosure can really help. Adds a bit of lift to the horn reverb as well. If you can place the sugar cube inside the shell close to the bell location it can help give the impression that the bell is really making the sound.

The other item I would highly recommend is a "keep-alive' for the Tsunami. Even though you have absolutely the best engineered pickups I have ever seen, there's always that chance of a nano-second power loss. That click followed by an engine start-up cycle can really break the spell when you're switching "in the zone"... $30 well spent IMHO. ![]()

Cheers,

Pete

Some of you may have noticed duplicate photos of the trucks. That was my mistake and I can't figure out how to remove the duplicate. Attached below is the photo I wanted to insert. Does anyone know anything about what's shown in the photo? I figure Gregg would want to know.

Jay

I think Bob Anson might have mentioned it someplace, and I confirmed it by looking inside of the original box. This unit came out of the Tony Ambrose estate, so I suspect that the first "brand" represents his initials. I don't know what the lower marking is that looks like a combined A, E and arrow.

As to the chronology, Bob dated the painting 1/21/89.

...gregg

and the numbers are probably amroses ssan

Pete,

I do have some of those small speakers. I may add one, we'll see.

As far as the "Keep Alive", I assume your referring to the use of these new super capacitors. I was talking to my friend, Joe West (the guy that modifies the Tsunamis for Protocraft) about just this thing. He told me where to make the electrical connections but I wasn't taking notes and I forgot. That would be another, we'll see.

I do thank you for your input though. Sometimes I wish more people would offer tips. Doesn't mean I'll use them but how else do we learn & improve?

Jay

Jay,

Looks sharp. Interested to see a photo of the drivetrain connections under the fuel tank. I'm looking for ideas for my S scale Smoky Mountain Model Works 44 and 70 ton locos.

Thanks for posting.

![]()

Nice installation Jay. It may have been said above so excuse me if I'm repeating but it sure sounds like I'm hearing wheel on tie or wheel on simulated tie nail noise in the video. Makes that zipper sound. Might have to check your wheel flange to tie clearance.

butch