Originally Posted by SantaFeJim:

I am currently in the process of designing a staging/storage yard for our club. The yard will be 8 feet wide and 45 feet long with a capacity of 700 cars. At the throat I want to put back-to-back Ross 11-degree WYE's. Each leg is 5.5 degrees from center. My question is, has anybody else done this? If so, can you run large locomotives(Big Boys, Cab Forwards, Challengers etc.) through them w/o problems? Did you need to add a straight section between the Y's.

Thanks.

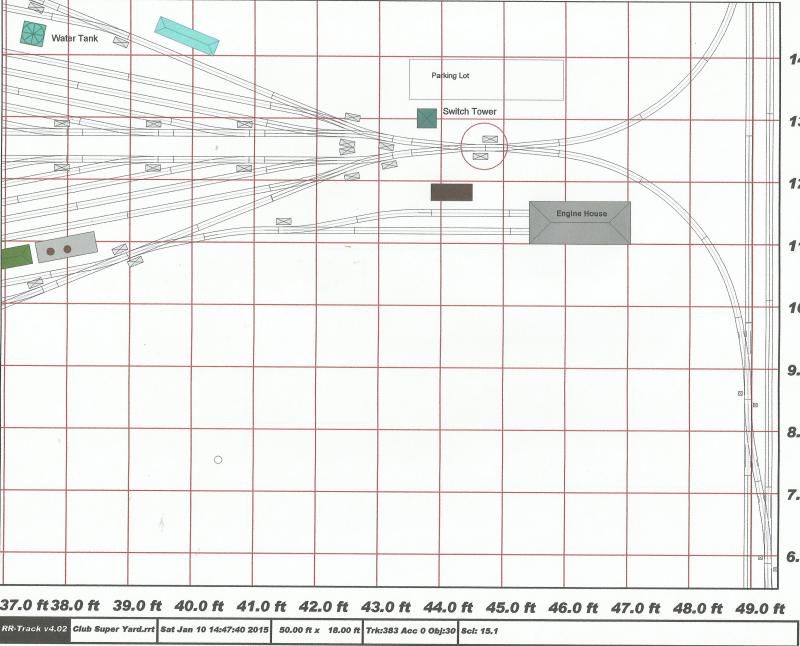

Here is what a yard ladder utilizing Ross 11 degree wyes would look like.

The above four tracks maintains a 4" track spacing, which is my preferred minimum, others will state that you can go closer.

Will a challenger / big boy / cab forward go thru it? Don't know. What I do know is that an MTH Great Northern R-2, 3rd Rail Z-5, Z-6, and Z-8 will not go thru a Ross "Y" ladder without derailing, nor will these reliably go through crossovers made with Ross 101 and 102 switches.

Reverse curves are the concern, and this will also be an issue if you are going to utilize Kadee couplers on long rolling stock.

The best way to test out what you want to do is to mock it up, and try it, or design conservatively. Conservatively, utilizing #6 switches, in the below possible configurations is the safest way to go.

Layout from the following link. The layout was with #4 switches, but the principle is the same with #6. Altas #5.5 would work well too, as was done on Hot Water's railroad.

http://cs.trains.com/mrr/f/11/t/187957.aspx

GNNPNUT