Well, I've got myself a new project. I am accumulating scale hoppers for a Reading Coal Drag. The problem is, all the hoppers I've been buying are empty! How do you guys make coal loads? Where do you get the coal? I've seen people use foam (styrofoam?) underneath to save material and weight, but how do you secure it?

Replies sorted oldest to newest

That is the method I use. No need to secure the load in the car, and as far as affixing the coal to the Styrofoam, a good thick coat of black latex paint does it. Latex paint is a good cement.

As far as sourcing the coal, any dealer who carries the Woodland Scenics line will have different sizes from which to choose.

Do it over a newspaper, and after allowing time to dry, shake and tap the load upside down over the paper. This way no coal is wasted. ![]()

Well, I've got myself a new project. I am accumulating scale hoppers for a Reading Coal Drag. The problem is, all the hoppers I've been buying are empty! How do you guys make coal loads? Where do you get the coal? I've seen people use foam (styrofoam?) underneath to save material and weight, but how do you secure it?

If you have a lot of empty hoppers, then contact St Charles Model works. I have used their coal loads on every one of the 80 some odd 2-Bay MTH coal hoppers I have (both C&O and Western Maryland). I think they are www.coalloads.com

You can also try Don Kane at Hopper Topper. don195657@yahoo.com

As a youngster, I used scrap and left over black roofing shingles to simulate coal loads in my Lehigh Valley consist. I cut the shingles into pieces that are slightly larger than the width and length of the hopper opening and then bowed it slightly making it rounded like a coal load. Fifty plus years later they are still there and visitors ask about it.

Reading RR had red dyed coal, so if you want to do some loads in red, go to the local paint store, and ask for a few squirts of the brightest red liquid dye, and dilute it slightly with water in a plant mister spray bottle. Spray the load, and let it dry. It may take a few coats to get the load an even color, then spray with a top coat of a clear finish to seal the dye. I made some of these for my Weaver 2 bay composite hoppers that were a club car run a few years ago.

Don

I cut 1/8 inch wood and recess it at 3/8 inch below the rim of the hopper then I put Brennans coal on top,very easy to do as the hoppers have a slope that starts at about 1/2 inch below the top of the hopper.

Mikey

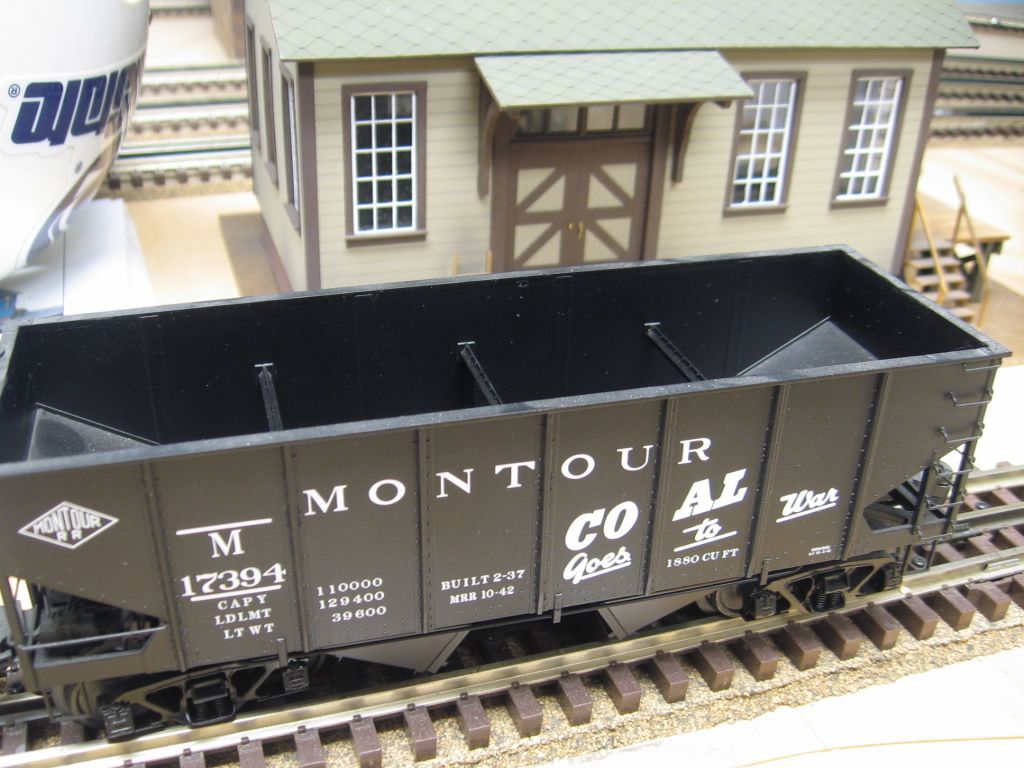

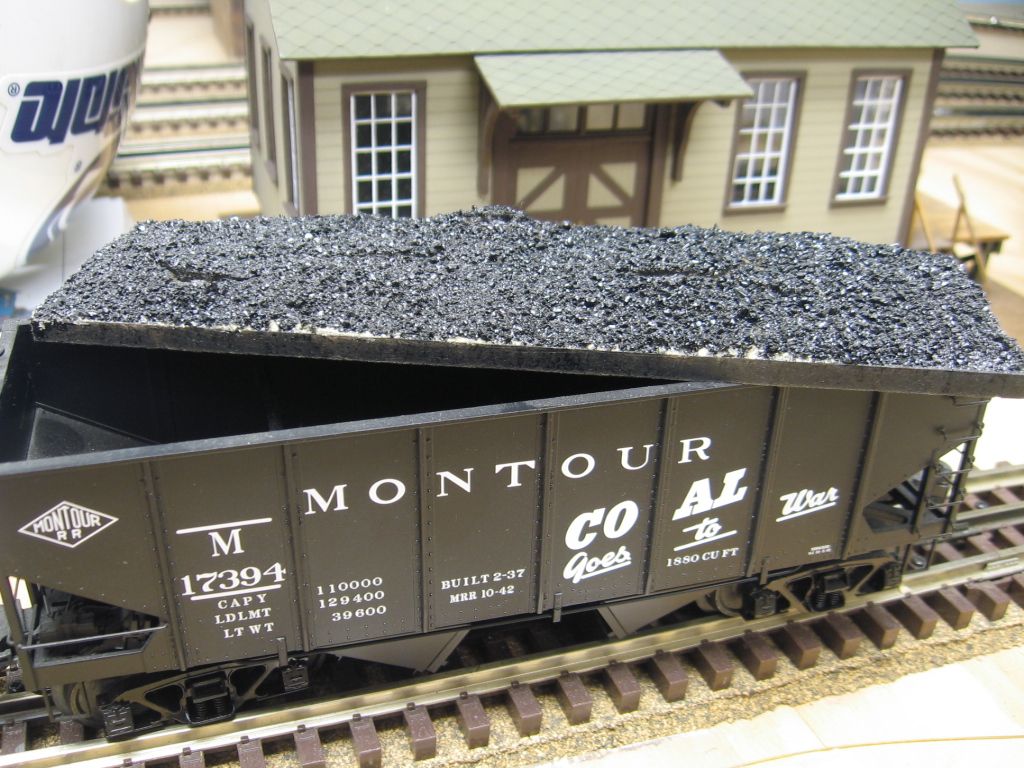

Some time ago, I made a few coal loads, but I used anthracite that I had smashed with a hammer and the size of the coal varied wildly. After reading two recent posts here about coal loads, I bought 2 bags of Conway Coal and 2 bags of Brennan Coal (way more than I needed). I made loads for all my hoppers to replace various plastic loads and to redo the foam ones I had previously made. I made half of the loads with Conway and half with Brennan. On average, I used about ½ oz. of coal per load. Here’s a brief comparison and a few steps on how I made them.

Conway Coal # 14 comes in a 12 oz bag. Brennan #3 is sold by volume, but a bag is about 13 oz. These are the sizes that they recommend for O scale. Brennan #3 is a wee bit larger, a little less uniform in size and a little cleaner (can coal be clean?) than the Conway #14. Conway also sells completed coal loads for some hoppers. I like both the Conway and the Brennan coal. All the loads came out looking great so I can’t really recommend one over the other. They look very similar when done.

BTW, the Brennan coal is Reading anthracite and the Conway coal was delivered to Conway years ago by either the Lehigh Valley Railroad or the Lackawanna.

Use 1” thick pink rigid foam insulation. Cut the foam into a rectangular shape so it fits snuggly in the hopper. If cut to the right size, it will fit snuggly after painting and won’t require anything to secure it in place. A table saw works great for cutting the rectangular shape but it has to be done CAREFULLY. You might want to use an old blade because if you don’t feed the foam perfectly straight, the blade will grab it and send it flying and/or melt foam onto the blade.

Place the rectangular foam block in the hopper so it sits on the slope at the ends of the car. Some cars have gussets so you may need to trim a bit off the foam to clear them. There is usually about 3/8” of the rectangular foam block sitting below the top of the car. Scribe around the foam along the top perimeter of the hopper.

Shape the foam to create coal mounds. Use a pen knife to cut a bit below the scribe line and make the rough shape of the mound. Use sand paper (60 and / or 80 grit seems to work well) to fine tune the shape.

Paint the foam with flat black latex paint (Krylon Chalkboard Paint or similar). Lay the paint on thick and cover it with coal. Let it dry overnight. After the paint is dry, remove any pieces of coal from the sides of the load and touch up to hide any pink.

It doesn’t take much time to make the loads and it doesn’t cost much.

Bob

Attachments

If they were MTH, you can buy the loads seperate. If not just do what everyone else is saying on this thread. Sorry If I didn't help out that much.

I use fish tank gravel and I also use beach(seashore) sand.

Conway Coal....can't beat it!

Using Black Beauty, a body shop sand blasting material. The templates are cut from 3/16" Masonite and a liberal application of construction adhesive is used.

Attachments

Thanks for all the information guys! It's lots of help, and a lot of different things for me to try, to see what will work best for me!

I think I'm going to go with the Reading Anthracite (ships on Reading Rails, and is a local company). I read somewhere else to use size three (mine run). How many hoppers (approximately) would a bag do?

Or should I be using a different size?

I think I'm going to go with the Reading Anthracite (ships on Reading Rails, and is a local company). I read somewhere else to use size three (mine run). How many hoppers (approximately) would a bag do?

Or should I be using a different size?

Size 3 is what Brennan recommends for O scale. I'll have to edit my reply above...not sure why I said size 8. If you make them using the rigid foam, you are just putting a coating on top of the paint so figure about ½ oz. per load depending on the hopper size. An MTH die cast will take a bit more and a Lionel 6456 / 6476 a bit less. You should be able to make about 2 dozen loads per bag of Brennan’s Reading Anthracite.

Or should I be using a different size?

Michael:

Unless you are absolutely set on making a complete train hauling "mine run" filled hoppers on their way to the breaker, you may want to consider trying a couple (or a few) different sizes. This way you can also model some cars filled with various-sized coal on their way to "market". Processed coal was sold in several sizes depending on its intended use. Just my thoughts...

I recently saw a model of a car carrying two coal sizes in the same car.

It was reportedly modeled on a divided hopper that was a common load for small, remote retail coal yards. The coal yards couldn't store two hoppers worth so they would order two half loads.

Never found any other information about this unusual load.

How come eastern mine coal lies relatively flat in the hoppers and coal from western mines have either two or three humps?

John in Lansing, Illinois

The load depends on the equipment of the time. Some companies had piles, and some mounds, while others had fairly flat loads. I've seen all types here in northeast Pa.

Modern auto flood loads have a mound that is flattened by the filler as the car passes under it.

Don

Well I just pulled the pin and ordered some #3 from Dennis.

Has anyone tried the #3 in any of the coal accessories ?

does it work any better or worse than the Lionel provided coal ?

Stoshu,

I would use #4 or #5 for operating accessories.