A small history of Atlas track.

(1.) Problem with rail joiners: First production track, the spring tension of the joiners was an issue, that caused intermittent track continuity problems. Replacement rail joiners were much better, but sometimes difficult to install.

(2.) Turnout problem (1.) Switch motor burn-out do to stuck push buttons. Corrected with the 6924 relay board.

(3.) Turnout problem (2.) Third rail dead spots, units/locomotives would loose power. Corrected with the 6924 relay board.

(4.) Turnout problem (3.) Rough tracking through a switch. In most cases, the switch needed to be flat/level. Sometimes adjusting/loosening screws, corrected problems.

(5.) Black center rail material would coat the third rail roller pick-up, and inhibit continuity. Usually removing the black coating from the top of the rail corrected the problem. Third rail pick-ups also had to be cleaned.

(6.) Later issue Atlas model engines were designed with (4) roller pickups, which also improved switch continuity problems.

(7.) Note: Atlas 3 rail curves were designed for 9" diameter increments, rails would be 5 1/2 (Edit/correction 4 1/2, thank you), center to center. O27, O36, O45, most common IMO, O54, O63, O72, O81, O90, etc.

(8.) There was an Atlas flex track, difficult to bend, IMO, worked best O72 and larger curves.

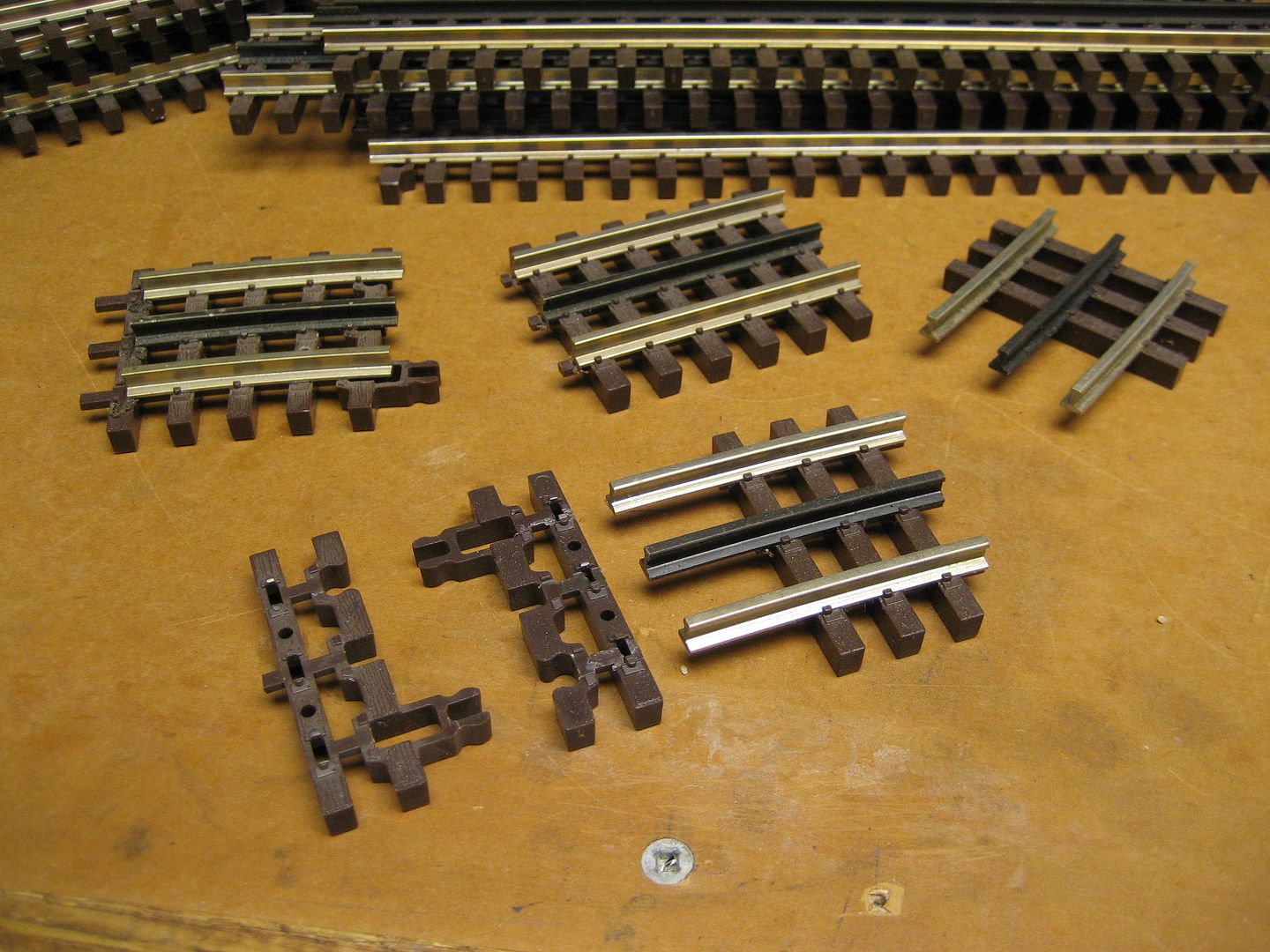

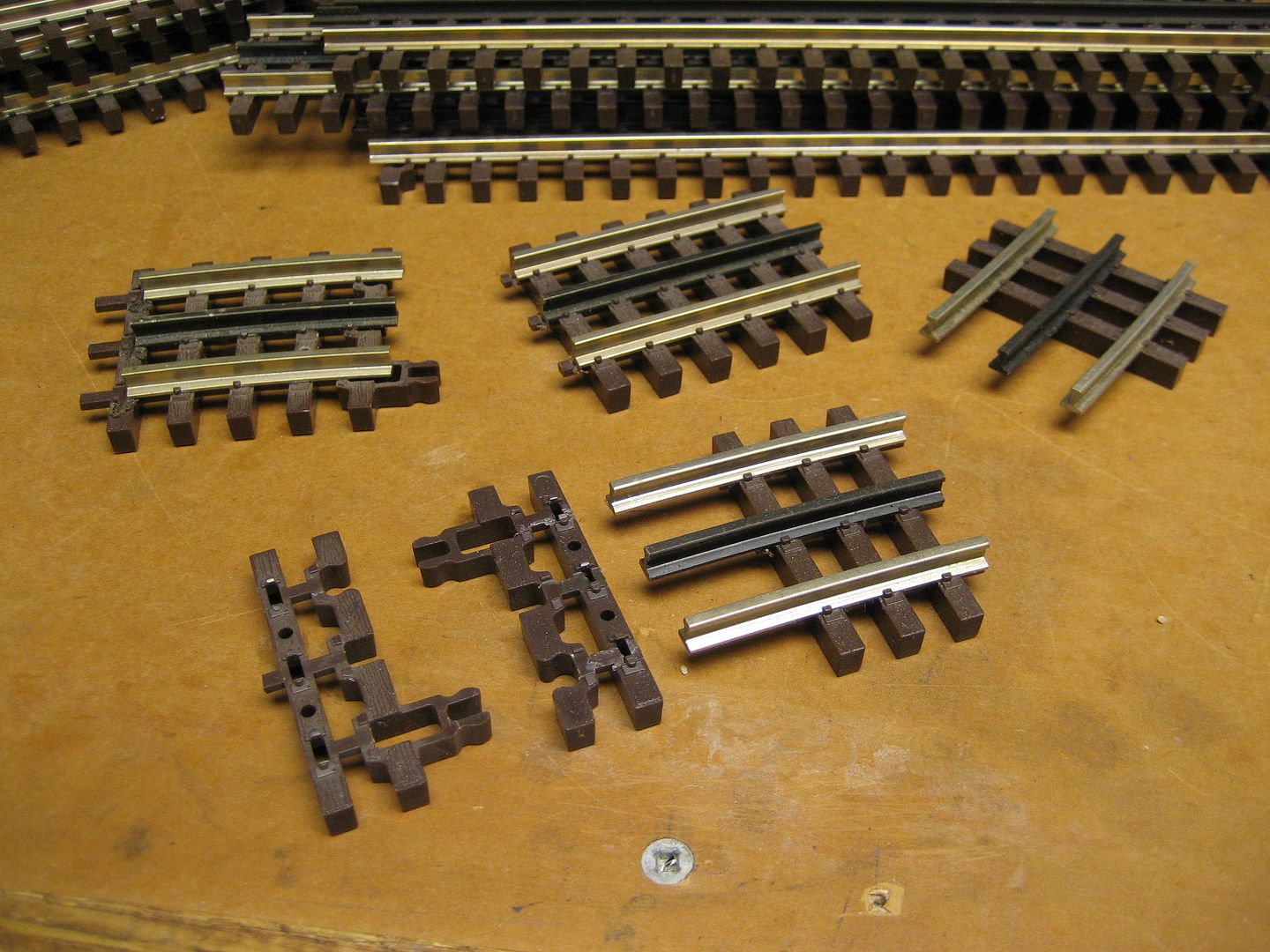

(9.) Atlas track components allowed for fabrication of custom pieces as needed. Example: pictured.

(10.) There were adapters to mate Atlas track with both Gargraves and Ross. I found the Atlas track joiner would work with both Ross, and Gargraves. The lower profile of Gargraves track, had to be removed with a dremel tool.

(11.) As with a lot of the hobby, (Built to order), may be, the most frustrating issue, as has been mentioned in this thread.