I think I have every gauge wire known to man in my wire box for my Lionel O-27 layout. What is the best size wire to use for track power as well as accessories?

Replies sorted oldest to newest

This has been discussed many times. Do a search for some very good information.

Personally, I use 14 ga for track and 16ga or 18 ga for accessories.

Accessories are somewhat of a wild card, typically #22 is plenty for any common accessory.

Track power depends on how far you're running it, it's more about voltage drop than current capability. A #18 wire can carry 10A safely, but it'll drop a lot of voltage on the way at significant current levels. Typically, track wiring is #12 to #16, depending on how far you are running, how much maximum current you anticipate, and how much voltage drop you're willing to tolerate.

John...I am very new to this forum and website, and this was my first ever post. I have O-27 on two 4x8 tables connected with bridges, and I'm sure I won't ever have the sophistication of many of this site's participants. I appreciate your advice, and I think I might toss all of the old wire scraps out and start over with new product.

I'd probably just go with #14, more than sufficient for that size layout.

"I think I might toss all of the old wire scraps out and start over with new product."

This would be a wise decision, IMO. That way, you'll have a fresh start with new product that you know.

I agree with John, 14ga suits the layout you've described. Be sure to buy / use stranded wire. You'll save yourself a few headaches.

Also, do the Forum search as I said above ... you'll learn as you move forward with the hobby.

Stranded 18ga is my standard wire for all uses

i'm far from the expert on electricity that others here are but I have set up an 11'x14' CHristmas layout for 30 some years, so I can at least offer an opinion based on what I do.

I use DCS and use the star wiring principle (have a central source and fan out from there). I use 14g or 16g to get from the trannie to that central point. BUT I use 18g from there to the track. With DCS one is supposed to isolate sections of trackage from each other based on where lockons (in my case) are placed. Therefore I have many lockons in place and I suppose this limits my exposure to low-voltage areas.

On the non-DCS set of track that's not needed so I just place a lockon every 8' to 10' or so, based on whether or not there are switches involved. I use 18g and daisy chain from one lockon to the next.

My trains always run well with no slow down spots.

My non-expert comment.

- walt

When I built 8x4 layouts for each set of grandchildren, I used #16, since no runs exceed 4'. For my layout, based on 75 years experience running trains, I use nothing less than #14 for trains. Experience has taught me that slight voltage drops have serious effect on these low voltage (18+/-) devices. If you have heavy load accessories, like #97 postwar coal loader, #14 also. For Z-Stuff switch motors, #20 is fine.

Signals such as for control system DCC, DCS TMDX or whatever are low amp and can use small gauge wire to get from the plugins to the control box. Connections to track power should be heavier gauge 14-15 depending on run. Drops from rail to buss, can be lighter gauge.

Here on the "Zero Budget Railroad" I use reclaimed electrical cords. Computers, appliances, old lamps, I cut off the cords before they are recycled/thrown away. My setup will not win the contest for best appearing underside but I will not melt the system down. Try flea markets and yard sales. A bag of random cords is cheap.

I wonder how one gets locos with a zero budget.

One other thing to consider is that no matter what you think you are going to do, it is going to change, so add a little extra wire on every accessory so you can pull it out and move it around a little. Also, although the advice about using only uncut wires is golden, it is not always practical. Sometimes, you start with what you think is enough wire and than discover that you need to splice a foot on to the wire. I think that if you want it perfect first, that's a great but unrealistic goal, especially in our hobby where time, supplies and budgets are often short. Don't be afraid to make mistakes. You will discover that you will learn more working out your mistakes than you might think.

Sometimes it is good to experiment and get whatever you are wiring working, than rewire it so that it has enough wire and looks cleaner. As frustrating as it is, the place we once wanted something, is usually not the place it should be or ends up.

If a frog had wings he would not bump his butt so much. Enjoy.

Just my .02.

Excellent suggestion....gracias!

Does OGR still sell wire?

Paul

One cannot err by using too large a gauge [within reason], but one can by using too small a wire, and the penalty is poor performance or a rewiring.

I for one do not subscribe to the theory of using smaller gauge drops. I want full power to each block. In fact, I run 14ga from control panel directly to each block. For common, I use a bare 12ga loop bus with frequent drops.

14ga is kind of a standard for the average (not small) pike for track power. Big pikes use 10 and 12 sometimes 14 based on the run. 18 or 20 is only used on short 12" to 16" drops to buss when a buss is used.

Yes, folks do run smaller. "I can get away with....." and "That is good enough" has never an approach of mine.

Do not forget to use a variety of wire colors to help service your layout.

It can be a snake pit without some order.

Attachments

TT, that panel is sickenly orderly![]() .

.

The wire rack/holder is interesting.![]()

Mr Muffin has been handling the wire that OGR used to sell. We got a bunch from them and not sure if they reordered.

O gauge ![]()

Got a bunch of those wire racks. Some supply houses and HD sell them. I clamp them in pairs on furniture dollies.

Jack C posted:I think I might toss all of the old wire scraps out and start over with new product.

With #1 scrap wire bringing a few dollars a pound-I hope you don’t just throw it in the trash.

Jack C posted:I think I have every gauge wire known to man in my wire box for my Lionel O-27 layout. What is the best size wire to use for track power as well as accessories?

make sure it is stranded copper wire nothing else

TT, I searched homedepot.com for wire racks and only came up with shelving. I can't picture what they look like raw.

However, I did find a Gardner-Bender Wire spool hand caddy, a bit pricey at $24 but looks like it's easy to make in my workshop

I only use 2 sizes: 14 gauge stranded for track power and 18 gauge solid for most everything else. I used 18 gauge stranded for flexible joints. I don’t daisy chain to save on wire. I do run buss lines to barrier strips.

Mike, that is a neat idea. Provides not only a way to carry the wire, but also strippers, pliers, etc.

Go to home depot web site, enter Gardner Bender wire caddy or Madison Electric wire caddy.

One is orange and $24 the other is blue and $28. Each caddy holds eight 500' rolls of wire.

14 gauge is your best bet. I use 14 gauge for feeders to the track as well.

Just saw this today, so apologies if I am answering an already solved question. Like Walt, I'm no where near the expert on wiring, Gunrunner John can tell you that. He helped me with my switch issue where I had to run the power through the track, not power them through external source. All I do know is that the way I have my layout wired currently appears to be working with no drop in power anywhere, no signal issues that I can see, and I can run three trains with 12 cars on three different tracks without blowing a circuit breaker neither on the TIU or the breaker box. So I am going to guess that I have sufficient power supplied to the track as well as no hiccups in the system that cause DCS signal issues.

20x20, give or take an inch or so, room with a big oval, a smaller oval inside that one, and a smaller oval inside that one. Inner most oval has five off shoot tracks that run the length of the oval back to it on the opposite end and act as parking tracks. All three ovals and parking tracks are connected as one unit, no separation of power supplies. 18 fastrack switches, all connected to a set of two AIU units because MTH saw fit to create them with only 10 switch ports and 10 accessory ports. So I had to buy two AIU's for 18 switches. I used 24 gauge telephone pair wires to connect the IN, OUT, and GND to the AIU 1, 2, and IN. Don't quote me on the Identifiers but you get the picture. All 18 switches, providing my remote batteries aren't weak, react immediately to any arrow choice as quickly as it is pressed. I love to use the ALL feature when I want to close the open switches. As for the 278 individual pieces of track that make up the layout, most are powered by virtue of being connected to the one in front of it and the one behind it.

However, following the advice of fellow O gauge forum members, I made it a point to run booster wires to 17 different location, one location of course being the terminal track piece that started it all. I used 16 gauge wire to come out of the Fixed IN1 port on the TIU and ran it to a 12 screw terminal board. I used said 16 gauge wire to hook the board to the TIU. Now using the 12 open screws, I knew I would need more than 12 to run my 17 drops. So I doubled up on 5 of the screws, and ran the last 7 to the remaining screws. I know, they make a 24 screw board, but i'd already bought the 12 and didn't want to send it back. It cost less to just double up where needed. I used 16 gauge wire to prep my screws. I put a pigtail wire under each screw, one red for the hot screw and one black for the ground screw. 5 screws had two reds and two blacks.

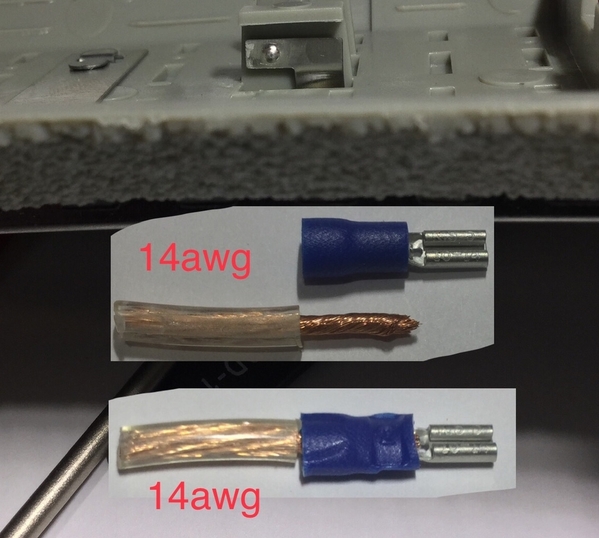

I ran 18 gauge wire from the connection points on the track to the 16 gauge wires under each screw. Why 18? Because anyone who has used Fastrack knows that the connection blocks under the straight pieces are tiny little sheet metal paddles. I call them "spatula" connectors. Yes, like a hamburger flipper. These spatula heads are barely an 1/8 inch wide. So the female equivalent that you have to use to connect a wire to these tiny little sheet metal pieces has to be small as well. The ones I bought are the bare back type, ones with no plastic sheath, just a bare stem that has two places to connect the wire. You connect your bare stripped wire strands under the clips closest to the female head, and you connect your still sheathed wire under the little clips at the back of the stem. Once you get used to it, a good set of needle nosed pliers works fine. Once I had them attached, I heat shrunk some heat shrink tube over the whole thing to help keep it all tucked in and tight. This is why I used 18 gauge wire instead of 16. It was easier to stuff 18 gauge stranded wire under those itty bitty prongs.

Once I had it all wired, I covered up all the ugliness using a false bottom shelf on my cabinet, turned on the TIU, added my engines to the remote, set an engine on the very back part of the largest oval to test distance issues, pushed button 3, engine cranked up like it owned the place. Rolled the whiz wheel up a few notches, engine immediately rolled off the starting block and before I knew it was doing 60 SMPH with no problems.

Before I did all of this, I had so many signal issues I was about to throw the thing in the trash. I had lionel engines starting up for no apparent reason. MTH engines were firing up spontaneously the moment I turned on the power switch. I got all sorts of engine not on track messages. But the tip from Gunrunner John seemed to eliminate any switch issues I might have had.

My question has been this all along. Best friend says it would not have mattered. Retired Professional Electrician said the same thing. Would using 12 gauge stranded wire from the TIU to the terminal board, and using that as my pigtail wires, would that have helped my voltage strength, or would using the 18 gauge wire have eliminated any improvements the 12 might have given me. Brett said no, Tommy said no. It's distance from the source that causes voltage drop, not wire size. Wires size is key to making sure you have large enough wire to handle the voltage pulsing through it. Otherwise you'd have a ton of breaker issues.

Thoughts?

"It's distance from the source that causes voltage drop, not wire size"

I that's true, I should have used 20 gauge instead of 14 gauge for my 25'+ runs.

The resistance of a wire is a function of both length and gauge. Try running 10 amps through a piece of 18- gauge and measure the voltage drop between the ends. But hey, it's your layout.

RJR

Not quite sure what you are trying to tell me. All I know is that so far, the 18 gauge I used to wire the track pieces to the terminal board appears to be handling things quite well. My friends told me that as long as the wire is sufficient to handle the voltage going through it, i'm ok. Granted there may be some voltage drop due to the size, but that's what I am asking. Are brett and tommy correct, or if I had gone with 16 throughout the run, would my engines be running any better than they are now? If so, I'll consider redoing the runs with 16 and just try harder to get the wire stuffed into those little connectors and improve my power output.

Thanks

"My friends told me that as long as the wire is sufficient to handle the voltage going through it, i'm ok."

Wrong. Amperage (current flow) not voltage is what determines the needed wire gauge. Voltage (pressure) determines how thick the wire insulation needs to be, and so is not a concern on the low voltage downstream of your transformer.

If you want to check voltage drop: Get an AC voltmeter. Set output voltage on the tiu. Go to a section of track and connect the voltmeter. It should read the same. Then run a train or 2 into the area of the voltmeter and see what it reads. Difference is your voltage drop. Without the load of a train or 2, the train cannot be run with ANY degree of accuracy---result is meaningless.

I have grades and lighted cars on a 38v16 layout. Any voltage loss magnifies the effect of these, so I use 14-gauge, with a direct connection from the control panel direct to the block.

When the layout was built almost 30 years ago, for a lowest level storage yards with 12 toggled blocks, I used 18-gauge wire (8 conductor cables) hot the hot feed, rather than the 14-gauge I used everywhere else. I figured that down there I'd be holding the transformer handle anyway, so slowdowns were no issue. Then along came DCS and the performance down there was terrible--poor DCS signals and operational issues. I rewired with 14-gauge and no more problems.

This is my layout and I have my own operational standards. I do not say others must use my system.

rthomps posted:This has been discussed many times. Do a search for some very good information.

Personally, I use 14 ga for track and 16ga or 18 ga for accessories.

If you have an old lighted caboose why not cut the top off and secure a voltmeter to it. Just connect the voltmeter to the wires that were on the light, then you can check the voltage under actual operating conditions. If you use 14 gage for track,and18 gage for accessories you won't go wrong. I don't like to use anything smaller than 18 gage as it is difficult to work with and is a little weak mechanically. Hope this helps.

RJR - Thanks for the clarification and thanks for the education. Until I wired my layout, I was used to wiring houses with my friend. Roll of 12-2 with ground, lots of holes, and the occasional 10 gauge and 8 gauge for 30 amp and 50 amp requirements.

FASTMAN and RJR - 14 would be great. However, as I mentioned in my initial reply to this thread. The reason for the higher gauge wire was due to the unchangeable reality of how small fastrack connections were designed to be. By the way I just got your caboose reply. Great idea. I might just take you up on that one. Back to my question. Will stranded 14 gauge wire fit in the connector I need to connect the wire to the track connectors? I can stick it under those screws and hook it to the TIU no problem, but when it comes to those track connections, that's a small area to work with.

I use MTH and 14 gauge wire.

I drill the holes in the MTH Lockons so the wire fits.

On my Gargraves, I use a bladed crimson to slide into the bottom of the rail, or I solder the wire to the side of the rail.

It speaks to the poor concern track manufactures have for customers, that they fail to provide adequate products.

Case in point-I buy my own banana plugs and make my own cables for connecting my Z4000 to my TIU. Because the MTH is junk.

1Drummer - Oh am I glad to hear from you. To anyone who is reading this reply to his reply, I do not wish to cast dispersions on anyone's loyalties to any certain product, manufacturer, or ideology, if there is such a thing, to Model Trains and how they work or should work. I also don't wish to get off of the subject of this thread. It's about wire gauge and I did throw in my two cents minus taxes worth. But that line about the companies not taking into consideration what the customers need, Amen.

You'd think if 14 gauge wire were better for the industry, the track would be designed to take 14 gauge wire. A hole with a screw, a screw you can hook the wire under, a hole with a piece that crimps down on the wire after it has been painstakingly slid beneath it, like the switch tracks, and the AIU ports. Terminal track pieces with special connection ports for those who wish to use larger wire. Connection ports that can be attached to an existing straight piece that will accept larger gauge wires. Having to solder wire to the track, come up with homemade remedies, and in some cases, as I have found since I got into this hobby, live with issues created by the manufacture of the product that I am discovering are not important and will never be corrected, "speaks to the poor concern manufacturers have for customers."

Now, back to the jist of this thread. Would it be possible to shrink tube the bare wire to the acceptable connector if I can't quite get all of it into the tiny connection prongs provided for the correct size connector that I have to use to slide it onto the connection point provided by Lionel?

Yardmaster -I’m not familiar with Lionel track.

Can you post a picture?

I'm sure I can find a solution.

Glad too. I'll post a photo of the connector I use as well. Thanks.

This is late to the party, but the .110” female connectors for FasTrack can be purchased in “blue” 14-16awg also. I’d have to check my records as to where I got them, but they are readily available.

Edit: Added photo