This reply is to everyone interested, but it's more directed to 1drummer and TedW.

I have enclosed 3 photos at drummer's request that show how fastrack is connected. TEDW enclosed a photo when he responded that shows a much better picture of fastrack and where the connection points are located under the track. So if you aren't familiar with fastrack, you have to connect to the hot and ground points underneath the track pieces, straights and curves. To add to the nightmare, only Lionel's specially made Terminal Track piece that has its own item number and is very different from other straight pieces in that the groove you need along the side of the track for the wires to protrude out from under the track is installed at the factory and the wires you need, which I think are 22 gauge, I may be wrong, are also installed at the factory and then you connect your wires to those wires. I hope the drenching smell of sarcasm isn't lost on anyone who read that.

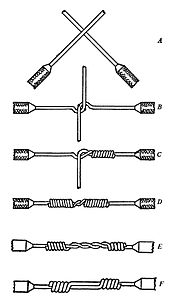

Photo 1 is a bad attempt at showing you what the connection clips look like. Again, thin, narrow sheet metal designed to take a wire connector that looks like photo 3, the clearest of my photos. TEDW sent a better picture of the underside but you can't see the silver sheet metal clips. But you can see how narrow the area is. TEDW, I too use those connectors, but from my photos you can see that I use the one's that do not have the plastic collars on them. My attempt with those photos was to show how narrow an area you have to put wire in them, and how shallow the clips are. Photo 2 shows, I hope, how close together both sets of clips are sitting.

I failed to mention in my first Gettysburg address, (sarcasm as to how long it was to read), my layout is on the floor. It's not on a table, or elevated in such a way that you can drop the wires into a hiding place, let them dangle, and have ample room to connect. The wires I ran had to be run out from under the track piece, along the side of the track, and finally through the bottom of the cabinet to the terminal board. Look closely between the cracker jack car under my hand, and the rice krispies car in front of it, that black spot is wide hook Velcro using the porch carpet as its loop side and holding down the wires.

So as you can hopefully determine from all this information, 14 gauge wire compared to 18, would be a bit more bulky in this case.....or maybe it wouldn't. But I was looking for ease of run along a floor so this is the best I could come up with at the time. Go thin, but don't go wrong. And to date it appears to work without complication.