This past Thursday I had the pleasure of touring the UP Cheyenne Roundhouse and Steam Shop with a group of friends from my train club.

UP Roundhouse from the Cheyenne Depot viewing area. The container car parked in front of the viewing window drew a few chuckles.

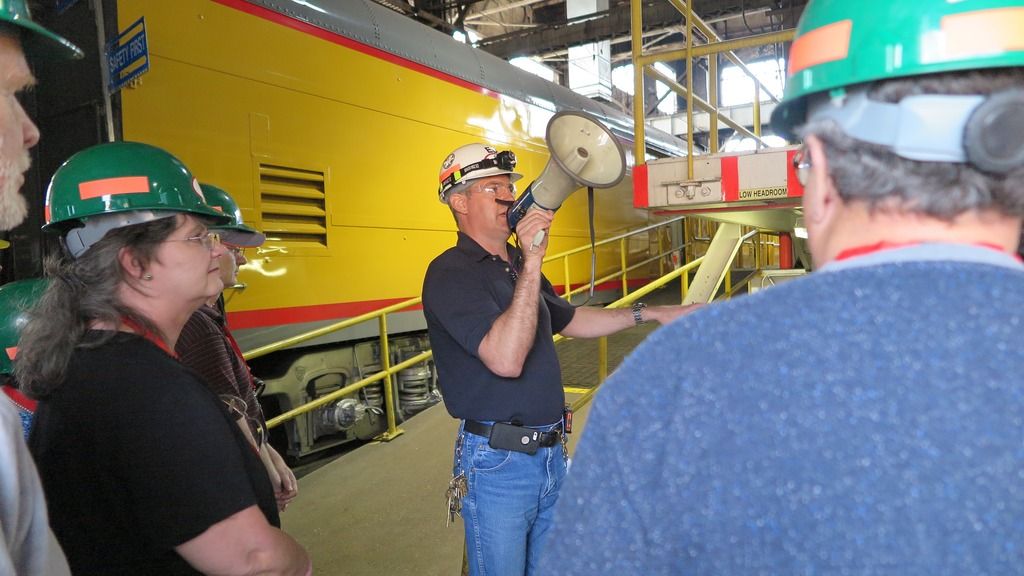

It was during working hours so manager Ed Dickens personally led us around while the work continued on 844.

This ones for Hotwater. ![]()

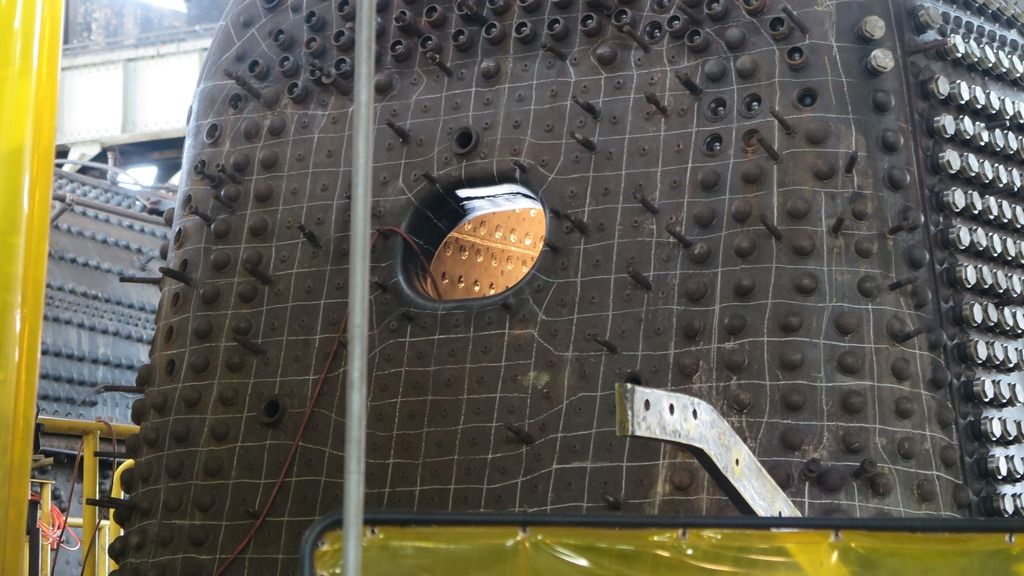

The boilermaker was working on one end below the firebox (didn't catch his name when introduced)

Another employee was actively removing flexible staybolt caps, inspecting and replacing Staybolts, seals and cups if needed followed by new caps.

Compared to photos from Depot Days several weeks ago it looks like they were making pretty good progress.

844's #4 wheelset in storage while boiler work is performed

A tray of new Staybolt seals. There were also many boxes of new cups and caps

The Boilermaker has marked of this end of the boiler/firebox for ongoing ultrasonic inspection.

Based on my visit a year ago changes to the steam shop so far it appear to be the known removal of the hung ceiling and what appears to be major repairs to the roof decking. It looks like a large percentage of the roof decking boards have been replaced. Looks like it was done right!

The windows look like broken panes have been repaired and sealed.

Crane has not arrived yet, platforms have not yet been removed and so far planned new lighting has not been installed.

Old rails for former 250 ton and 40 ton cranes.

Elsewhere in the shop 4014 is waiting for attention.

Replacement parts have been ordered for 4014 as shown by the many boxes of coil springs for the engine and tender.

Included are inner and outer centering springs for the front engine.

Also inside the steam shop was the Rotary which had some maintenance , repairs and updates done to it.

That was it for the Steam Shop. Roundhouse next.