@Mallard4468 posted:It's not quite on the workbench yet, but...

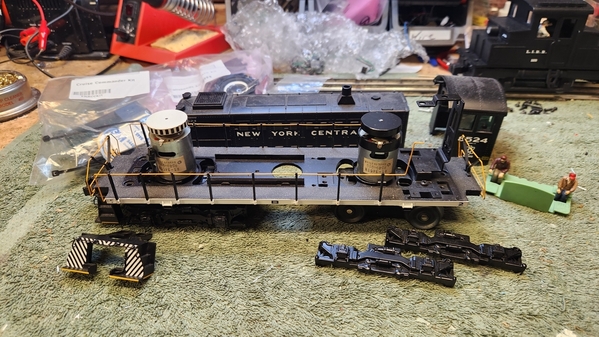

Awhile ago, I built a Frankenstein steeple cab loco from a MPC switcher and a couple of slope back tenders. As a result, I have two short tender frames. Here's a pic of one of them:

Trying to decide what to do with them. Leaning towards something whimsical - some kind of short caboose, or maybe put a beer can on it. Suggestions are appreciated.

I love short wheelbase projects.

Only one suggestion, though - no beer can. So often seen, and almost always a waste of a nice beginning.