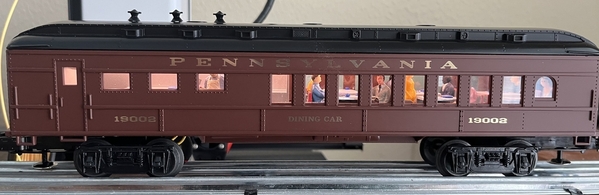

Inspired by @Sitka's #41 US Army switcher project, I just finished lighting this MPC-era Lionel Marines bunk car from 1984:

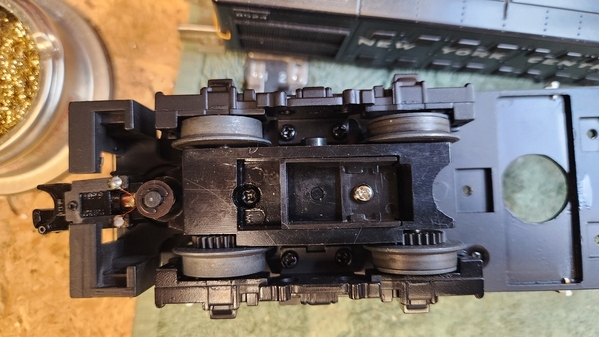

I used Evan Designs 3mm universal 7-19v "bulb" LED kits recommended by @WesternPacific2217. I mounted them "slip-fit" using sections of spray bottle tubing so they can be replaced. The tubes also allow for some diffused light inside the car. Fortunately, the arch-bar trucks were designed to accommodate a standard "snap-in" pickup plate. To reduce flicker, I added some car weights over the "pickup truck" end of the car.

As Tom Bodett says at the end of his Motel 6 spots, "We'll leave the light on for ya'."