@Mark Boyce posted:Thank you too, Craig! So you can teach an old dog new tricks! It just takes a bit of clarification. 😃

Craig, thank you for the photographs of the instructions. They look straightforward, but offer several variations! I like it!! 👍🏻

That was certainly quick and easy. I programmed the Weaver RS3 and the video shows the results. Actually it runs even slower, but I had trouble setting the speed and holding the smartphone to get the video. Thank you Bob, Pete, Craig!!

Great job Mark! All I can say is you all are a lot braver then I am! LOL ![]()

@Mark Boyce posted:That was certainly quick and easy. I programmed the Weaver RS3 and the video shows the results. Actually it runs even slower, but I had trouble setting the speed and holding the smartphone to get the video. Thank you Bob, Pete, Craig!!

Looks great Mark. Glad it was a simple fix.

Bob

Thank you, Mike and Bob! I was half expecting it not to work the first try, and I would have to do it again. That is what happened on my two PS3 upgrade file loads.

@Mark Boyce posted:That was certainly quick and easy. I programmed the Weaver RS3 and the video shows the results. Actually it runs even slower, but I had trouble setting the speed and holding the smartphone to get the video. Thank you Bob, Pete, Craig!!

My pleasure and loooks greeeeat

@ThatGuy posted:My pleasure and loooks greeeeat

I was disappointed with it when I got it, but I should have known a reprogram would help.

@Mark Boyce posted:That was certainly quick and easy. I programmed the Weaver RS3 and the video shows the results. Actually it runs even slower, but I had trouble setting the speed and holding the smartphone to get the video. Thank you Bob, Pete, Craig!!

Looks like a really good speed Mark. Nice job. ![]()

( instead of holdoing the smart phone get a phone holder with an adapter and and mount it on a tripod maybe? ![]() )

)

@Dallas Joseph posted:Looks like a really good speed Mark. Nice job.

( instead of holdoing the smart phone get a phone holder with an adapter and and mount it on a tripod maybe?

)

Thank you, Dallas! You have a good point. I can tell some some others are using a tripod and some kind of holder because their videos are so steady. Also, if I had just done a runby with the engine already moving, I could have just left the remote sitting on the layout, hands off.

@RSJB18 Great job on your Weaver RS 3!

”I'm very pleased with the results and the install was simple compared to doing a full ERR or PS3/2 stacker. Safe to say I'll be upgrading more basic engines with this method. ![]() “

“

Funny your simple scared me off. Thinking about all those connectors that you were dealing with.

@pennsyfan posted:@RSJB18 Great job on your Weaver RS 3!

”I'm very pleased with the results and the install was simple compared to doing a full ERR or PS3/2 stacker. Safe to say I'll be upgrading more basic engines with this method.

“

Funny your simple scared me off. Thinking about all those connectors that you were dealing with.

Those little plugs do look intimidating. I bought ready made harnesses as recommended by GRJ. Much better than trying to build them from scratch. Just not worth the aggravation. ![]() In the case of the LC boards, the plugs are labeled so it's easy to know what to connect to each.

In the case of the LC boards, the plugs are labeled so it's easy to know what to connect to each.

Thanks

@RSJB18 posted: Much better than trying to build them from scratch. Just not worth the aggravation.Thanks

Well if we didn't spend sooooo much time on the FORUM getting a plethora of ideas for our layouts we would have more time and peace of mind to DIY. ![]()

God speed Bob.

@Dallas Joseph posted:Well if we didn't spend sooooo much time on the FORUM getting a plethora of ideas for our layouts we would have more time and peace of mind to DIY.

God speed Bob.

Dallas, for folks like me between layouts its a great time to collect ideas! LOL![]()

@Dallas Joseph posted:Well if we didn't spend sooooo much time on the FORUM getting a plethora of ideas for our layouts we would have more time and peace of mind to DIY.

God speed Bob.

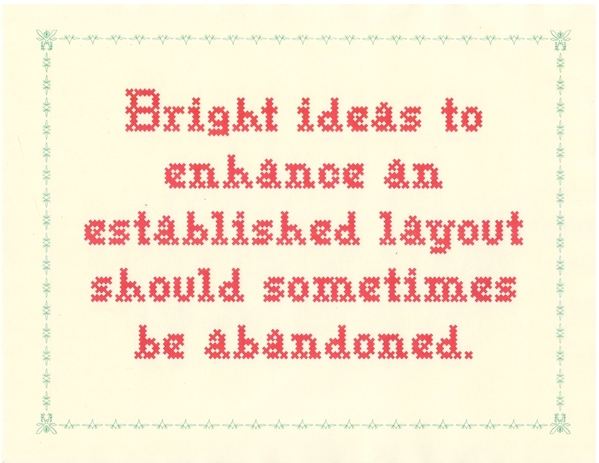

It’s the ideas that get me into trouble; mainly my own, e.g. I had the brain storm to create an elevated subway track. It eventually turned out ok after two years of aggravation. That’s when I coined this phrase; and someone liked it so much they made a simulated needle point. It’s now hanging at the entrance to my train room.

Attachments

@mike g. posted:Dallas, for folks like me between layouts its a great time to collect ideas! LOL

@pennsyfan posted:It’s the ideas that get me into trouble; mainly my own, e.g. I had the brain storm to create an elevated subway track. It eventually turned out ok after two years of aggravation. That’s when I coined this phrase; and someone liked it so much they made a simulated needle point. It’s now hanging at the entrance to my train room.

Beautiful thoughts gentelmen .![]()

@Mark Boyce posted:That was certainly quick and easy. I programmed the Weaver RS3 and the video shows the results. Actually it runs even slower, but I had trouble setting the speed and holding the smartphone to get the video.

Nice work Mark! I have absolutely no idea about the inner workings of these locomotives and I appreciate what I learn from the members. Heck, I had no clue what a BCR was until I heard it from Mr. Muffin’s latest York video.

Gene

@Genemed posted:Nice work Mark! I have absolutely no idea about the inner workings of these locomotives and I appreciate what I learn from the members. Heck, I had no clue what a BCR was until I heard it from Mr. Muffin’s latest York video.

Gene

Thank you, Gene! It's like someone who doesn't understand the inner workings of their car. You don't have to understand it to use it. You just need to know who to contact when there is a problem! ![]()

Took the RS3 apart last night to fix the rubbing of the flywheel against the cab interior.......Missed by about a 1/8" so now I have to take it apart one more time........![]()

Bob

@RSJB18 posted:Took the RS3 apart last night to fix the rubbing of the flywheel against the cab interior.......Missed by about a 1/8" so now I have to take it apart one more time........

Bob

Ugh!

@Mark Boyce posted:Ugh!

Yea........although I used more colorful language.......![]()

It's hard to measure the parts because the interior has to be installed inside the cab. It looked like a 1/4" had to come off but it's closer to 3/8" plus.

Bob

@RSJB18 posted:Took the RS3 apart last night to fix the rubbing of the flywheel against the cab interior.......Missed by about a 1/8" so now I have to take it apart one more time........

Bob

Perhaps you should consider a malted beverage prior to recommencing.

Well, I have a pair of Atlas GP60s, one powered and one non-powered, all apart and in the process of making one complete to upgrade to PS3. I had upgraded an Atlas GP60 to PS3 a month or so ago but couldn’t figure out how to install the proto couplers. I left the TMCC couplers installed in it. I ordered the short MTH couplers and had them on hand thinking that they might work better than the longer ones that came with the upgrade kit. When I received the two locomotives that are now on the bench, the powered one was not in very good condition. Several screw posts were broken, the shell was cracked and there were several broken railing stanchions among several other minor problems. I decided to used the non-powered shell, chassis/frame and pilots and transfer the motors and trucks from the damaged one. I figured out what to modify to attach the MTH proto couplers. Just took a hacksaw, a little filing, proper orientation of the modified piece, a “T” post, spring, #10 washer and an “E” clip. I had to make the holes larger in the pilots and frame to make room for the coupler wire connectors to fit through. I have headlights, number board lights and backup lights installed. Now all I need to do is install the PS3 board, decide if I want to use two TMCC 8 ohm speakers in parallel (not using smoke unit so there should be space) or use the kit speaker and install the nano LEDs, for the ditch lights, when they arrive from Evan Designs.

Larry

Sounds like a good project, Larry! I used some parts from a non powered F3 to complete my powered F3 PS3 upgrade.

Attachments

@Tranquil Hollow RR posted:Perhaps you should consider a malted beverage prior to recommencing.

Like Ovaltine?

@coach joe posted:Like Ovaltine?

Don't think that's exactly what Jay had in mind Coach. ![]()

Comes with the territory when dabbling in the fine art of engine bashing.......

At least it's only an RS3- 4 screws and the shell is off......not a steamer.

Bob

![]()

![]()

![]()

![]()

I've started my project, inspired by the work of @RSJB18, to update my Lionel 9510 PRR Combo Mail/Baggage/Passenger car I bought NIB from eBay. This will be pulled by new PRR doodlebug.

I've attached a picture showing it's current state of, well whatever it is. In the middle of the picture is the roof. Taking it off was no small task. I then cut off the molded plastic that doubled as windows making it super easy to put the roof on, and it stays securely. Lastly I put is some small warm white LED strips to provide lighting on both sides of the car. Except for attaching the wires, that part is done.

At the bottom of the picture is the body. I've enlarged the holes for the wires so there is no binding. I will eventually put in thin, clear plastic windows for all the openings. After that is done, that is it for that part.

The last part is at the top, a wooden base I cut that will fit into the body. The cut outs you see are for some plastic tabs molded into the body. I also put some weights under the wooden base since this car is extremely light. I am waiting for several things to come in, so this part is nowhere near completion, but I'll describe what I've done and what my plans are. I will eventually paint the wooden base black.

In the middle of the base is a section of a large molded interior piece I had left over from another project (it's actually 2 bathrooms). With a little grinding, it fit perfectly in the middle to separate the passenger compartment from the mail/baggage area. I have a hole in that part, along with the wooden base, to run the power wires up to one of @gunrunnerjohn's lighting module, which will feed my LEDs on the roof. I'll craft a door to cover the opening on the passenger side. Also on the passenger side I'll put a lighted scale wall clock on the front bulkhead. I don't know if that's prototypical for this thing, but I like clocks.

I had a few wooden bench seats left over from another project, however I need more. It took a bit to find where I bought them, but they are now on order. I bought some Bachmann Trains waist-up seated passengers from Amazon to populate it. I put one of the guys in a seat, and looking through the window the result was perfect.

I am waiting for an REA Station Agent at a desk sorting mail to put on the mail/baggage side. That piece is large enough to cover the opening in the bulkhead leading to the passenger side. I have some other people and miscellaneous stuff to fill out that area.

Attachments

@texgeekboy posted:I've started my project, inspired by the work of @RSJB18, to update my Lionel 9510 PRR Combo Mail/Baggage/Passenger car I bought NIB from eBay. This will be pulled by new PRR doodlebug.

looks good so far. Certainly was a fun project for me.

Happy to provide some inspiration.

Bob

Looks like a good project, texgeekboy!!

You guys sure are brave in what you all dig into to make better! I know I will do the same thing one day, but as for me that is way down the road. I know last time I did it was because I had idol hands just watching trains go round and round!

Wonderful work thought and I hope you all keep it up!

We need a sub-forum....What's OFF the Workbench........![]()

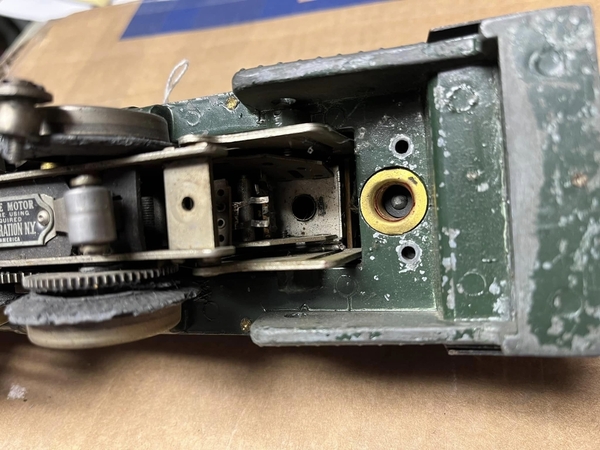

Rainy day here on LI yesterday so between moving my son home from College for the summer (and putting all his c#$p away), I finished my Weaver Lionchief upgrade. I had to open it once more to cut the cab interior down a little more. All went well and I can now declare the project done and a success.

I will definitely be doing more of these upgrades on some select engines worthy of the time and expense. Total cost for the parts was $99.00

The cab interior wall was hitting the flywheel which is visible now but from standing height, it looks fine. Also installed a new horn which was missing.

On to the next one.....maybe I can get my Morris Park Switcher done.....still needs more painting and final assembly.

Bob

Attachments

@RSJB18 posted:We need a sub-forum....What's OFF the Workbench........

Rainy day here on LI yesterday so between moving my son home from College for the summer (and putting all his c#$p away), I finished my Weaver Lionchief upgrade. I had to open it once more to cut the cab interior down a little more. All went well and I can now declare the project done and a success.

I will definitely be doing more of these upgrades on some select engines worthy of the time and expense. Total cost for the parts was $99.00The cab interior wall was hitting the flywheel which is visible now but from standing height, it looks fine. Also installed a new horn which was missing.

On to the next one.....maybe I can get my Morris Park Switcher done.....still needs more painting and final assembly.

Bob

Nice work Bob, looks and runs nice and smooth!

@mike g. posted:Nice work Bob, looks and runs nice and smooth!

Thanks Mike. The motors are wired in series since the LC boards only have one motor output. In the video the track is at 16vac. I used the universal remote for the video, but with the LC app it will crawl almost as well as a Legacy or PS3 engine.

Bob

Nice work, Bob! $99 👍🏻

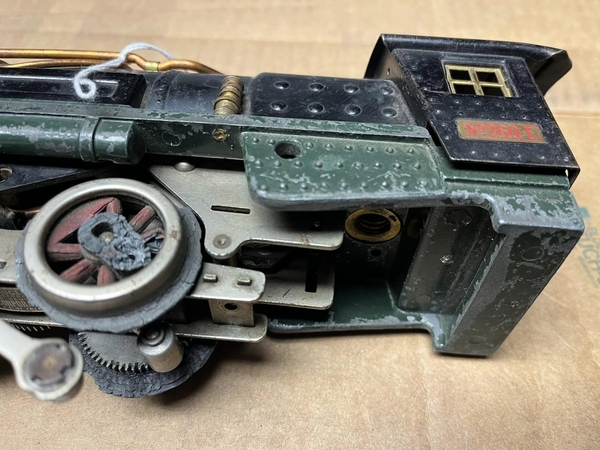

Need to find a couple of good wheels for this Green frame 260E I picked up from a local antique shop recently.

Attachments

@Dennis Holler posted:

Congrats on another great find. Bet she will be handsome when you’re done!

@Dennis Holler posted:Need to find a couple of good wheels for this Green frame 260E I picked up from a local antique shop recently.

Drop Train Tender a line; he can get you fixed up. ![]()

Mitch

I found my 264 forklift in a box deep in a storage bin!

It had been 20 years since I had the pleasure of buying it at YORK. Come to find the solenoid was this decade DOA! Never liked the inconsistency and noise of that solenoid, so no worries.

After doing a little research (a great thanks to OGR member “Junior”) I became brave enough to enable the DC motor conversion. The process took an entire day! There were sweaty palms, shakes hands , physically cramped area of work but no failed attempts, the lighted head visor helped. I am fortunate for the historic post and discussion that motivated me. See link below.

Working on dialing the best voltage.

It was an eye opening adventure for me. Glad I had the time to invest. It was definitely worth it!

https://ogrforum.com/...7#154307984447670917