quote:

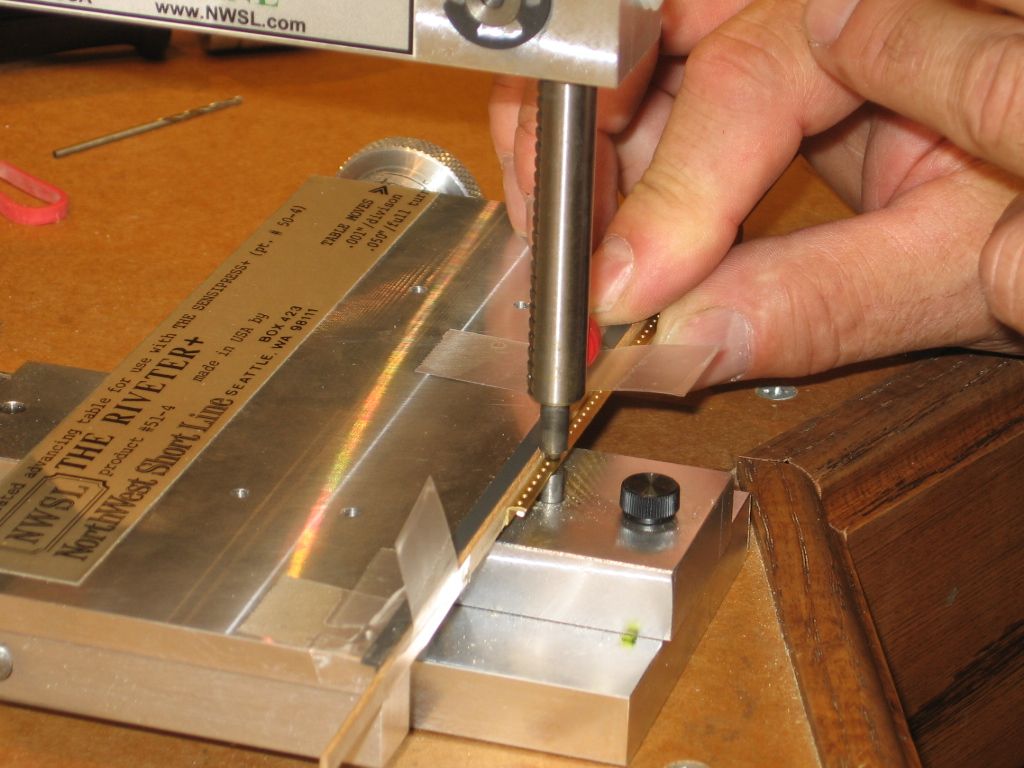

I was originally using the thumb screw and using the lock nuts. I talked to a few folks that recommended not using the thumb screw and only the top lock nut to allow some "play" in the holder to help with alignment. In the photo, neither the thumbscrew nor the bottom lock nut is used.

When configured with only the top lock nut, because of that play I can almost get the ram and the anvil in the same plane. It still bends the rivet slightly. When using the thumb screw and the bottom lock nut as well, the alignment is not as bad as in the photo, but there is also no play so the rivets bend more.

I've been using a Hobby Horse press for around 29 years.

IMHO, you really do not want play in the anvil holder.

Adjust the anvil holder so the ram is not going all the way down. I have owned four Hobby Horse Presses of different vintages, including two of the customized ones for Lionel. I've also examined several more. When the ram is fully extended, they tend to cock slightly, causing a mis-alignment.

Also, the press does not automatically align the rivet. One has to be very carefull to make certain that the shaft of the rivet is straight so the rolling clincher is hitting it squarely. The rivet will also bend/crush if you use a clincher that is too small. The original Chicago Rivet Clinchers have a somewhat semi-circular "ball" at the tip that expands the semi-tubular rivet's tip. I find that the nicest clinch is achieved when a tiny bit of the ball is visible when I test fit the rivet to the clincher. If none of the ball is visible, it willl crush.

With a little practice, you should be able to form rivets that look just like they came from the factory.

Did you buy your press new?

Regardless, if you continue to have problems, I suggest you contact Carl for advice. He makes the presses, he should be able to give you the best advice.

http://hobbyhorseproducts.com/