Originally Posted by zhyachts:

Originally Posted by Adriatic:

My Grandfather used the ceramic resistors to drop voltage behind the train in the 70's with ZW's, but there was only conventional locos back then. He used 8 blocks on each of the 15 x 30 passenger loops (2). Mostly two a-b-b-a war bonnets, and double & triple headed Lacky teams. The only big issue was too fast a start up on some once power returned to full. But he slowed that eventually too, I forget how. The cars eventually got caps for the lights too I think.

I don't remember any fuses, but they may have been under the control stations lid. I still have a half dozen extra ceramic resistors in a parts drawer.

Adriatic

I may be wrong, but isn't block control for trains operating in conventional mode? With speed control blocks should not be needed for collision avoidance. i only operate in conventional mode.

It wasn't meant to be personal Bill.

Only my experience with a layout I grew up around.

One that sounded like quite similar in a way.

I should back you. A fuse is seldom a bad idea.

I just don't remember any.

I am being made to think, and change my normal "circuit use" thoughts, to working with a much larger canvas. So, I am learning.

Learning what was likely done under our layout once, from just reading this.

Thank you.

I assumed the jack-rabbiting was use of relays.

I'd seen the resistors, but had never given anything other than fleeting thought to the theory of their uses, or looked up the part numbers on them to know for sure what they are.

I had assumed for the moment, the extra numbers might be important. I guessed they were the thermal fix for the jack-rabbiting. A thermal resistor that dropped resistance with temp.

Now, I question my original "quick theory" greatly.

The old one, with all powered units, long trains, 8 "sections", approx. 15x30 rounded box Gar Graves. It used ZWs. I don't remember fuses.

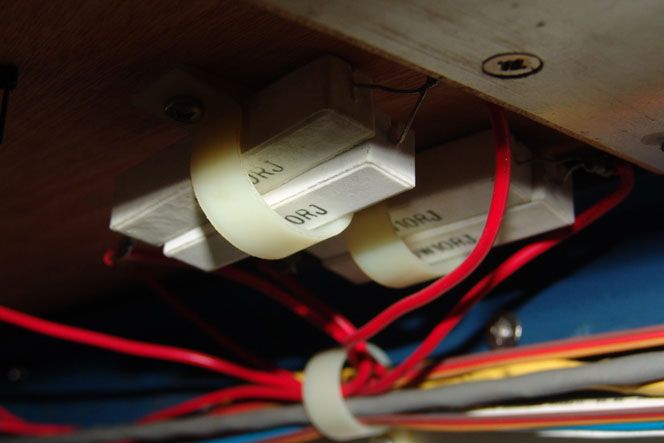

I do remember banks, as is 9+ of those (hot..ouch ) ceramic resistors on the underside, in 8 spots. With up to six motors on a section, yes, banks of them.

) ceramic resistors on the underside, in 8 spots. With up to six motors on a section, yes, banks of them.

I only run conventional too.

I don't know why I mentioned no command.

An unconsciously made disclaimer to anything I might ad?

To nip at the bud a "Change to command" post that may follow?

Conversation filler?

Anyhow, again not personal

Now this is.....

My favorite "speed control" is four blocks, 2 grades, E-33, & a prewar Z

Being "loopy" and 1/3 the size of the old layout, I keep it to one train per line .

.

With a drawer of resistors, I'm now getting urges for use elsewhere.

Ok...The E-33 is tmcc, but I don't own a system.

Ok...The E-33 is tmcc, but I don't own a system.