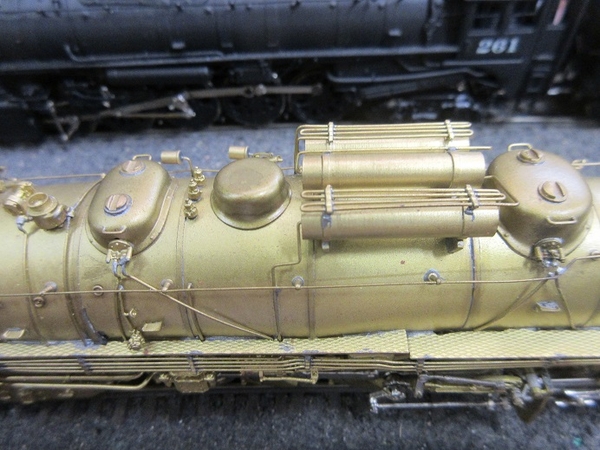

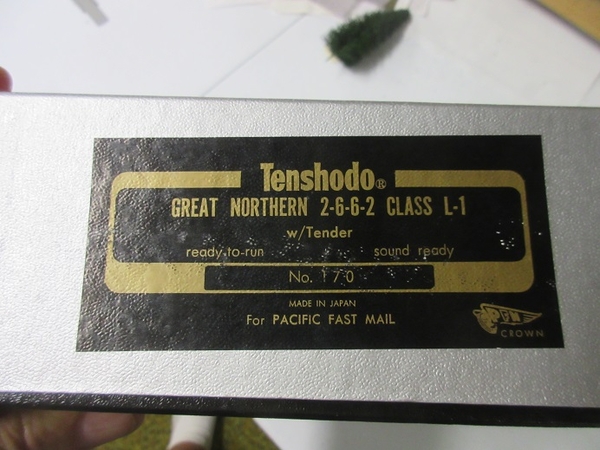

Southern MS-2 duplex 2-8-2 + 2-8-0 painting.

An engine most people didn't know that Southern possessed.

Imported by Westside models in 1978.

This engine will be much easier to paint as, besides the basic black, it only has a red roof.

Prep:

Bench test to insure no binds.

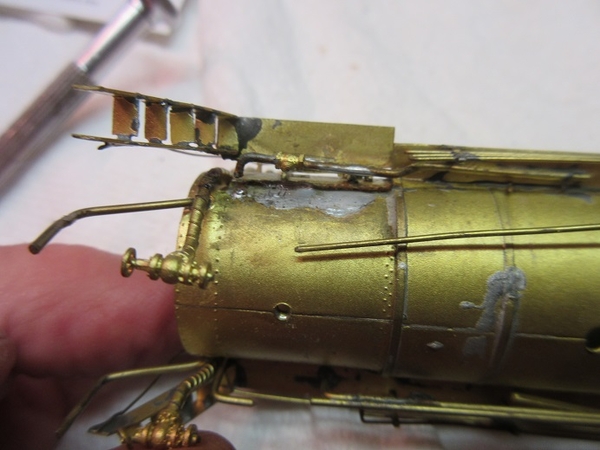

Some resistance soldering on a water pipe...

and a steam pipe.

No marker lights so only needed to 'drill out' the headlight' and 'running board light' holes and cab.

Took pictures for reference when assembling.

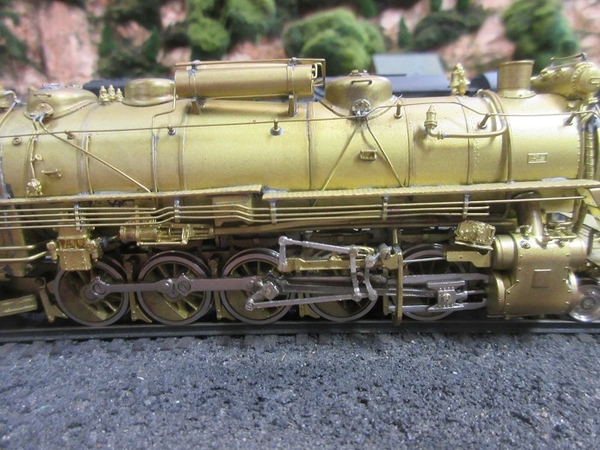

Front drivers are 'standard' but...

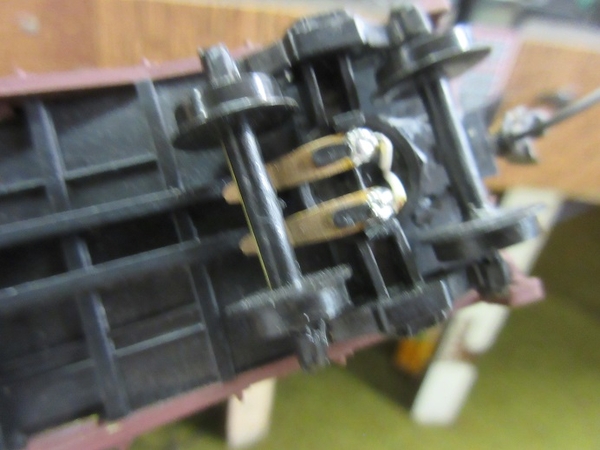

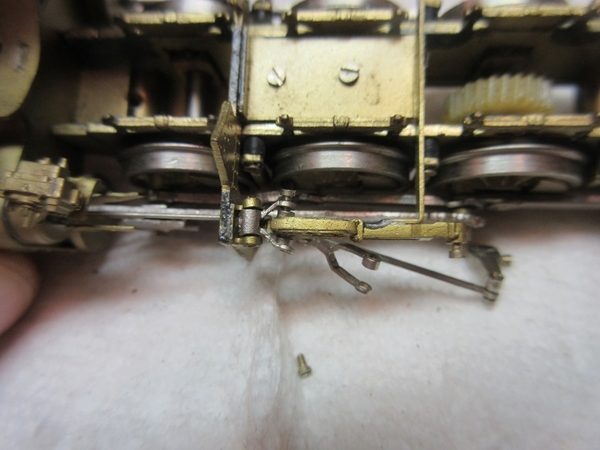

The tender drivers has a complex valve system.

Fortunately it was well done with lots of screws that can be, easily, removed.

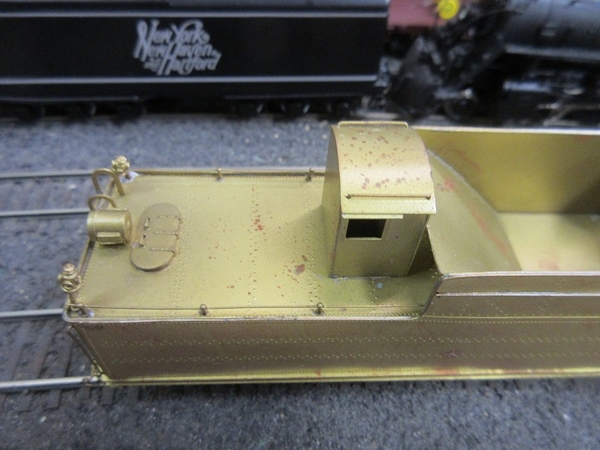

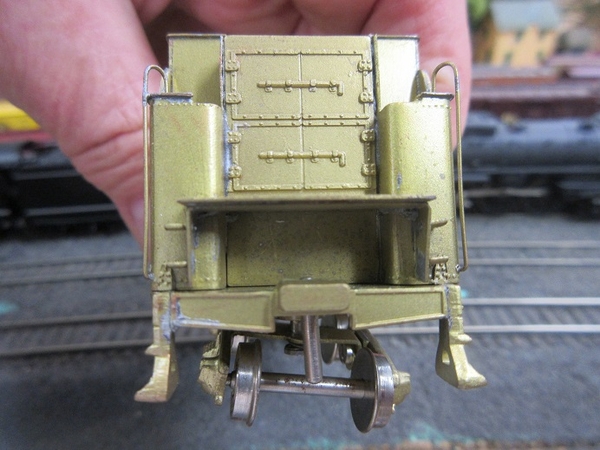

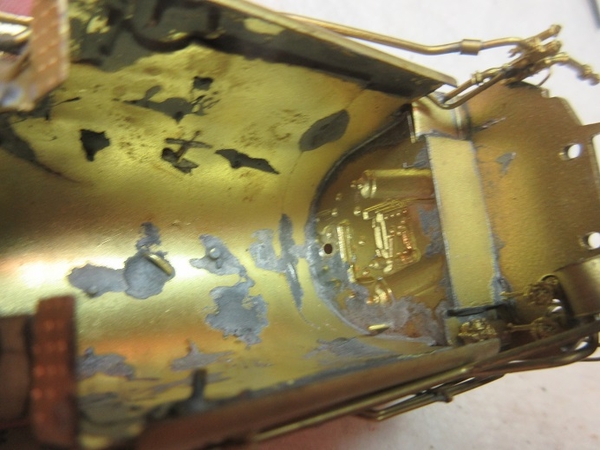

Tender 'drive system'.

4 screws need to be removed to disassemble the valve gear; per side.

Amazing they can make such small screws and 2 of them have 'shoulders'.

Left side.

Right side.

Put all the screws back 'in place' so I know where they 'go'!

Front valve gear only has 1 screw.

Not sure 'why' but there was scotch tape on both pistons.

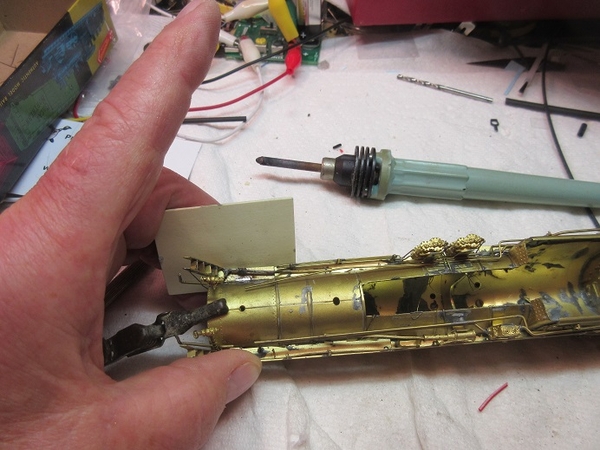

I always disassemble all 'screwed on' parts but unable to 'do so' with the back drivers.

A piece of brass base kept the 'valve support' gear from being removed from the frame.

Also, the frame made it impossible to remove the pistons.

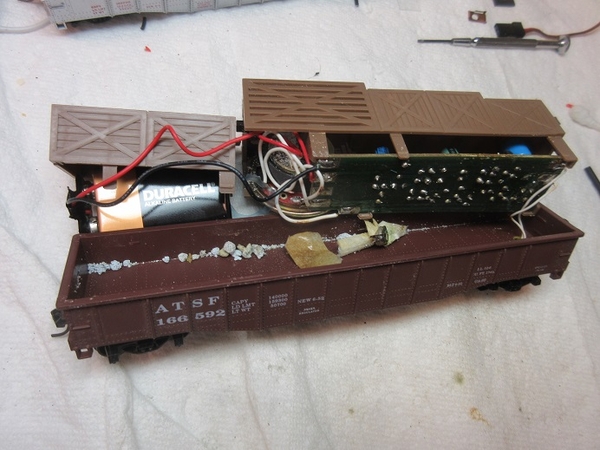

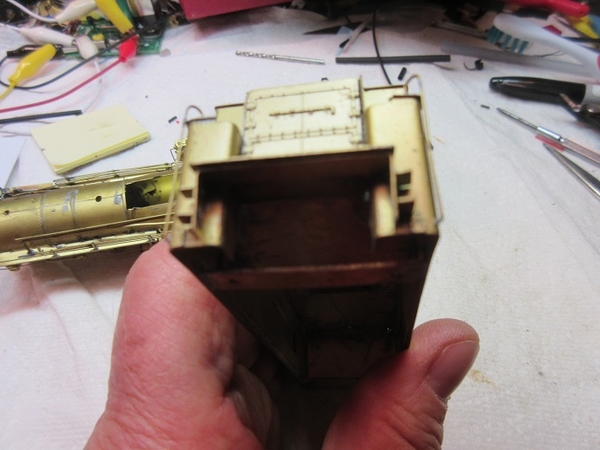

Drilled holes in the 'coal bunker' for the speaker.

If unable to have an internal speaker due to the motor and gears, will place it on top of the coal bunker and cover it with foam.

Drilled 2 holes in the bottom of the tender to route wires.

Alternate location for wires at the front of the tender.

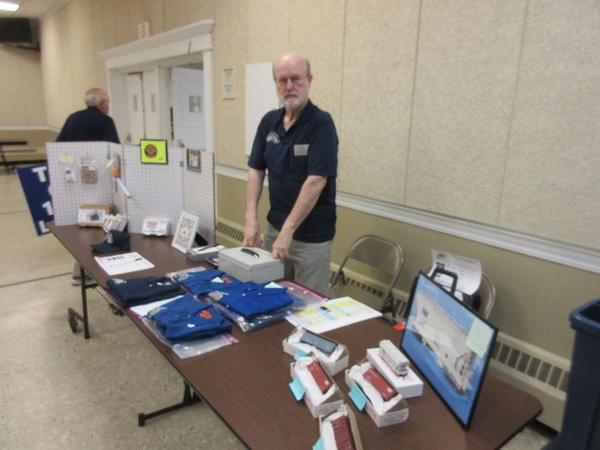

Parts ready to be cleaned.

Tender wheels.

Boiler wheels.

Parts that won't be painted.

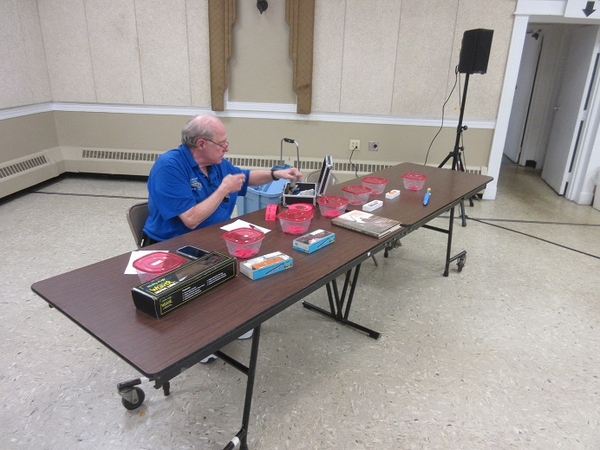

Parts cleaned and 'air compressor' blown dry and in toaster oven for 15 minutes to remove any remaining water.

Will be 'air dried' when painting as the trailing truck is 'soldered' and has no screws for disassembly.

I always 'air dry' wheels so not to 'dry out' the 'insulation' wheel if put in a toaster oven.

The 'insulation' could shrink and the tire will 'fall off' the rim.