Watched a number of videos including from Lionel (workbench wed and layout tips and tricks, wiring fasttrack) demonstrating soldering jumpers between fasttrack sections to improve electrical connectivity. Several of the videos suggest doing this to all the sections. While it is easy to see how to solder long sections together that can then be flipped over, the videos don't mention how you connect these long sections of jumpered track to each other to complete the layout. Do you just use longer wires to jump between sections so you can flip them once connected and then snap the adjacent jumpered fasttrack sections together. Or is the goal if you want to use jumpers to only place them between the track sections between feeders and not all the sections.

Replies sorted oldest to newest

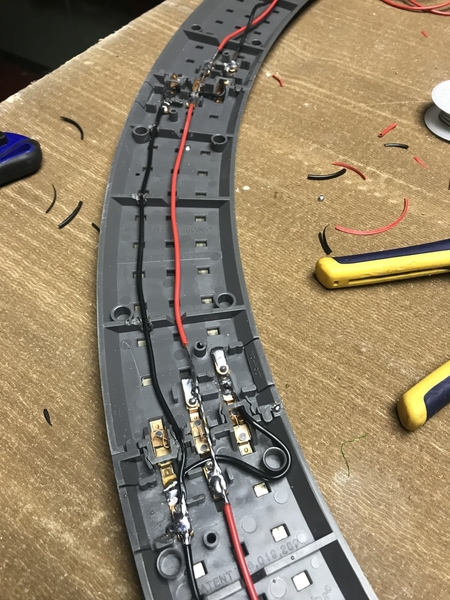

I soldered every section of my MTH track on a 6 x 20 layout. Where the 054 curves connected to the long straight runs, I came down with long jumpers. These are wire nutted together under the table I then have 4 total leads to my transformer. Over kill maybe but it works. I also put clear silicone on the bottoms of the track, sorry no photo. This added weight and quiets the track. None of my track is screwed down, I just have scenery up to it.

Attachments

D

Thanks for the response. Figured you had to do something like that with long jumpers to join sections. Odd that they don't address this in the videos. Are the red and black wires running under your track your bus wires.

@HJS posted:D

Thanks for the response. Figured you had to do something like that with long jumpers to join sections. Odd that they don't address this in the videos. Are the red and black wires running under your track your bus wires.

Yes, I did red for the center rail and black for the outer rails so it would be easy to get it right going to the transformer.

WOW Dave, and here I thought that I was going overboard with jumpers! I heard that it wasn't necessary to also do the ground, so I only have it intermittently, what are your thoughts on that? I am still in the process.

HJS, I am still working on mine and have multiple jumper wires but mostly on the shorter pieces. I recently came across the same issue as you but so far was fortunate enough that the feeder wires were long enough that I could fully turn over a section to then add and even solder the next. I don't worry about every single section being soldered but maybe I should. The more we do, the more we learn.

Mikki

Mikki, to each his own, I had Fast Track before and experienced dead spots and rust a few years after my build. I had heard the copper loops at the end of the MTH were their Kryptonite. Rather than taking a chance on future issues I chose the over kill method of soldering everything. I am currently making a change to the layout going from 6 x20 to 6x13 with a turn to make it L shaped. So, since it worked so well before the new 7-foot section will be done the same way.

Dave, I started out with FT via my first train, a gift at the age of 55 or so. It was a Lionel Ready to Run; I was totally new to model railroading and only knew this and the tubular of my childhood. The FT worked great for the Holiday Train show that I put up and took down each year as well as playing around in my basement. The next thing I knew I had a TON of it so it would have been pricey to start my new layout with something new (would love something more realistic). I have some of the MTH track and actually dislike it as the same thing that causes it to not come apart, causes me to not be able to separate them when I want and broke a number of them trying. I don't design with a program, I use paper, colored pencils, a scale ruler and templates for curves. Then I "play" with the track to get it right. That means lots of trial and error.

I will be adding more jumpers but can only do so much soldering at one time. Fortunately, I have no rust issues. Wiring is NOT my favorite part, and I can't wait to do some landscaping and populating.

Mikki

thanks for all the responses. any other thoughts out there on how to join together long sections of jumpered fasttrack. was also thinking of using a 5 position wemo connector between the longer segments of jumpered track to act like a feeder/jumper where the two jumped segments come together. Two for power in and out and two feeder/jumper. two sets, one for hot and one for ground. Will have feeders within the longer jumped segments as well.

D

Finally finished wiring my large layout using your 4 long drop feeder wire technique to join together sections of wire joined soldered fasttrack. Used Wemo connectors to join to the bus lines. Worked great. Thanks for the suggestion. Appreciate the help.

H

I soldered every joint from the top, but only in areas where the track will be hidden later. Where the track is exposed I added a feeder every other track. (The track is screwed into position, though)

Attachments

I'm just the opposite with my Fastrack, I make sure I have good continuity between the rails.

I use a pair of small needle nose pliers and slightly squeeze the rails. This ensures there is full contact with the pins of the rails.

If I pick up a piece of track and shake it, and the pins rattle, I remove the rail, remove the pin and then squeeze the rail. Put the pin back in and re-assemble. The rails should NOT rattle.

I use a OHM meter and check continuity between the connecting rails. I may assemble 4-5 pieces of track then check.

I have recently bought some new Fastrack and found the rails wider than normal, so no contact when connected.

This is either poor or no QC at the factory.

Bending the pins only breaks the pins. Squeeze the rail, it does the same thing as bending the pins and you wont break them.