Replies sorted oldest to newest

I know how everyone enjoys these updates and they may not subscribe to Facebook.

A "bit too large" !! And they reduced 1 " - seems like a lot to me. I thought they were talking about 1/16" or something. We will see how it works.

Congratulations UP Steam Team, looks like they are making progress, and that's a good positive!.............

If the down sizing of tubes are from the factory engineered drawings, and have been checked against the old tubes that were removed, all should go well. I know that swedging in some of the water tube boilers that I worked on in days gone by, was Engineered for velocity changes, and residence time during the heat exchange process.

Probably this may be the same thing they are doing here.

I wouldn't believe anyway shape or form, that they ordered too big a tube, and swedging it to fit, so as not to purchase the correct size. I've been wrong before, just time to get off their back and let em walk awhile!............................

It seems to me they've introduced a lot of stress into that pipe by cold working it.

Also the spacing between the various "large" diameter flues is a lot tighter. Thus the amount of water flowing between them will be far less. (See video for how the spacing has tightened up).

With the flow rate reduced, and spacing being a lot tighter, wouldn't sediment build-up potentially overtime close off those passageways? If that were to happen, could you develop trapped steam pockets? If so what would the consequences be?

I'm not a boiler expert by any stretch of the imagination, so these are my theories based upon my life long engineering experience.

It would depend on the metallurgy of the tube, how they can work it.

Back when I did similar work for a living, depending on the metallurgy, there was a tremendous amount of annealing we did to tubes after the welding process was complete. This boiler being a fire tube, I really don't know what the MFG's would require. Temperatures are considerably higher, but the rest I don't have a clue.

I know we had to follow what our Inspection Dept called for, and they followed the MFG specs, to the old proverbial "T".

Maybe "Hot Water", will get on here, and gives us some answers.................

Guess I am like St. Thomas the Apostle: I will not believe it until I see it, or a vid of it, moving under her own steam.

Oh, come on now Domi, just think when they get it running again, all of us Nay Sayers, can stand down by the UP Main Line, and Rich and Hot Water can lead us in some verses of "Bringing in the Sheaves"........................![]()

![]()

Brandy posted:...Rich and Hot Water can lead us in some verses of "Bringing in the Sheaves"........................

That was my Dad's favorite hymn.

As for the video update, all I can do is chuckle...

I was amazed and shocked that they would cold work the diameter of a boiler tube that much plus you really narrow the passages between the tubes. All that could really affect fluid flow and heat transfer. Time will tell. Hope they don't have to retube the boiler.

jim pastorius posted:I was amazed and shocked that they would cold work the diameter of a boiler tube that much plus you really narrow the passages between the tubes. All that could really affect fluid flow and heat transfer. Time will tell. Hope they don't have to retube the boiler.

Water shell side around the tubes, and flue gas through the tubes!................

I would think that the larger diameter tubes would give of course more surface area, and then the swedge, engineered to control residence time, and making a ventura to increase the speed into the smoke box, then there is the stack nozzle/nozzles!.......................Yeah it time for a Yuengling Black and Tan..........too much thinking here.....![]() ........

........![]()

lets just leave the amateur comments out and just enjoy the trip to whatever the 844 gives us.

ironlake2 posted:lets just leave the amateur comments out and just enjoy the trip to whatever the 844 gives us.

Spoken like a true boiler expert!!!!

Yes, famous last words !!

They may use the diesel's more this time, than what they have in the past!.....Recon their in good shape?????????????

My question is, what's the size of the hole in the tube sheet? It would have to be 5 1/2" minimum to fit a 5.5" pipe through it. You're not sticking a 5.5" tube through a 4.5" hole. Is there a spacer that goes over the end of the tube to take up some of the space as it gets rolled into the sheet?

What really gives here?? Instead of talking in tongues, it would be nice if someone qualified would comment.

Thanks!

Why wouldn't you just replace the pipe with pipe the same size as the holes in the end piece? Just wondering.

Clarence Siman posted:Why wouldn't you just replace the pipe with pipe the same size as the holes in the end piece? Just wondering.

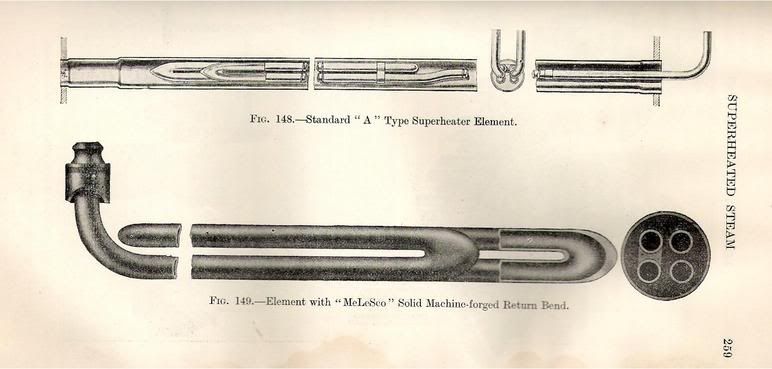

Because the larger flue tubes must contain a Type A superheater unit, which is inserted into the flue from the front end, thus the flue must be noticeably larger in diameter in the front, with correspondingly larger holes in the front tube sheet. The flues are then wedged down in OD to a smaller diameter to be inserted into the rear tube sheet. The flues/tubes are about 21 feet long.

Thank You Hot Water. Once something is explained to me I understand the situation better.

Brandy posted:Oh, come on now Domi, just think when they get it running again, all of us Nay Sayers, can stand down by the UP Main Line, and Rich and Hot Water can lead us in some verses of "Bringing in the Sheaves"........................

I think the more likely song is something from Steven Soundheim: Bring in the Clowns!

Brandy,

There are specific requirements/specifications for railroad boiler flue/tube material, i.e. it is NOT "pipe". The flue/tube requirements are for seamless TUBING, with specific wall thickness for the application.

Hot Water, do they install the swedged tubes into the crown sheet then tig weld them to the crown sheet, and roll the other ends???

Why I was asking that's the way I helped an old timer that was retubing a boiler on an old Keck- Gonnerman Steam Tractor, just after getting home from Nam in the middle 60's.

I just don't know how they would do it on a steam Locomotive boiler.

I remember reading the C&O 2789 was suppose to have a 100% welded boiler.

With reading that, I thought both ends were welded, but how would that expand ,and contract, with out separation, or a minimum cracking??

Hot Water posted:Brandy,

There are specific requirements/specifications for railroad boiler flue/tube material, i.e. it is NOT "pipe". The flue/tube requirements are for seamless TUBING, with specific wall thickness for the application.

Yes you are correct on the terminology of seamless tubing, but also as you said it does have a thickness requirement, along with all of the rest of the Metallurgy for the said application. And that's why they call it boiler tubing, boy all my buddies would like to hear about this one! They would probably drum has *ss out of the Boiler Makers Union.....![]()

It seems to me that one end, or the other, of the tube sheets would have to be able to slide, as the tubes lenghten or contract, depending on whether the boiler was starting up or shutting down.

disclaimer: never seen inside a locomotive boiler, or spent any time studying its design

I think I ran the video four times, just to make sense of the process.

So, assuming the superheater elements are successfully inserted into these modified fire-tubes, then what? Hasn't the tubing been work-hardened too much by the first forming dies to be re-swaged into the tube sheets, or are they straight welded in?

Do the tube-sheet assemblies need to be built around these modified flues, as opposed to the flues being fitted into the tube-sheets, 'cos them's too big?

Less space = better water circulation? How come?

Eyeball headache....................![]() but note spaces respectfully left for Hot Water

but note spaces respectfully left for Hot Water ![]()

Well, sure hope the boiler tests are successful.

Interesting....guess we'll see what we'll see.

Attachments

Well Gary. I hate to burst your bubble, but the man who did this work to 844 the last time said over on Trainorders that the absolute EARLIEST all the needed work could be finished would be September, and that's if everything went perfectly.

Quote from UP.com...

"As work began on the flues, the team ran into an unexpected challenge. Critical parts arrived in the wrong size.“The material we ordered was supposed to be in a specific diameter, but it arrived a little too big,” said Ed Dickens, senior manager of Heritage Fleet Operations. “To solve the problem, we had no other alternative but to make a machine to fix it.”

So that whole video showing them re-swedging and patting themselves on the back is just one of many twists in this bizarre fable of coverups...what a bunch of rookies...the mighty UP should be embarrassed to even release a video such as this.

Casey Jones2 posted:Quote from UP.com...

"As work began on the flues, the team ran into an unexpected challenge. Critical parts arrived in the wrong size.“The material we ordered was supposed to be in a specific diameter, but it arrived a little too big,” said Ed Dickens, senior manager of Heritage Fleet Operations. “To solve the problem, we had no other alternative but to make a machine to fix it.”

So that whole video showing them re-swedging and patting themselves on the back is just one of many twists in this bizarre fable of coverups...what a bunch of rookies...the mighty UP should be embarrassed to even release a video such as this.

Not to mention that those new flues/tubes were purchased from the Milwaukee 261 group, and have been sitting on the floor in Cheyenne for almost a year. Such a statement raises some questions:

1) Why wasn't the incorrect size noted upon receipt from the 261 folks?

2) Why was there a "mistake in the size" anyway? Did someone on the UP steam crew measure the holes in the tube sheets incorrectly, or did the 261 folks not follow the specifications of the flue/tube diameters ordered by the UP?

3) If the "error" was/is the responsibility of the supplier, i.e. the 261 group, then why hasn't the supplier been notified and required to correct the "error"?

4) If indeed the "error" was the fault of the UP steam shop personnel, then why publish such information that makes everyone in Cheyenne look like incompetents?

Casey Jones2 posted:Quote from UP.com...

"As work began on the flues, the team ran into an unexpected challenge. Critical parts arrived in the wrong size.“The material we ordered was supposed to be in a specific diameter, but it arrived a little too big,” said Ed Dickens, senior manager of Heritage Fleet Operations. “To solve the problem, we had no other alternative but to make a machine to fix it.”

So that whole video showing them re-swedging and patting themselves on the back is just one of many twists in this bizarre fable of coverups...what a bunch of rookies...the mighty UP should be embarrassed to even release a video such as this.

Ah, poor 844. We knew thee well. RIP.

With all the discussion about the UP steam crew -negative/positive, I didn't form an opinion. Not being a steam engine expert or restorer I felt I shouldn't judge. I cannot believe-in their own words "critical parts arrived in the wrong size"- and they did nothing about it except to squeeze the tubes to make them fit !! Not just a little bit -an inch on a 5 1/2 tube is whole lot. Having been associated and dealt with people on boilers a lot goes on in heat transfer. Surface area, velocity, pressure especially at the temperature and pressure the engine would be working at are very critical. These people do not have clue what they are doing. If this loco ever runs right it will be a miracle.

jim pastorius posted:and they did nothing about it except to squeeze the tubes to make them fit !! Not just a little bit -an inch on a 5 1/2 tube is whole lot.

From what Hot Water posted above, isn't this the process that is supposed to happen?

"Because the larger flue tubes must contain a Type A superheater unit, which is inserted into the flue from the front end, thus the flue must be noticeably larger in diameter in the front, with correspondingly larger holes in the front tube sheet. The flues are then [s]wedged down in OD to a smaller diameter to be inserted into the rear tube sheet."

I will follow the thread but no more comments. These guys must have been working on the Pennsy K4 1361 in Altoona. To take a critical part to a big, powerful piece of machinery like the 844 and "make do" like they did is insane. End of story.

So...if the larger, front portion of the flue is indeed the correct diameter (and I'm *assuming* it is because they don't seem to be changing anything about that end), then the problem is at the rear flue sheet.

It sounds like the holes in the flue sheet are too small.

So, maybe this is a silly question: Wouldn't it have been easier to simply open up the flue sheet holes to the appropriate diameter, rather than "building a machine" using a "100 ton hydraulic ram" to swedge the flues down in diameter?

smd4 posted:So...if the larger, front portion of the flue is indeed the correct diameter (and I'm *assuming* it is because they don't seem to be changing anything about that end), then the problem is at the rear flue sheet.

Yes, sort of, i.e. the rear sheet itself was/is not the problem.

It sounds like the holes in the flue sheet are too small.

No, not at all, as they were the correct size for the flues/tubes that were removed. All that should be required is the ever so slight reaming of the holes in the rear sheet, by only removal of about a few thousands, in order to insure a good clean (nick free) surface when the flues are rolled & beaded.

So, maybe this is a silly question: Wouldn't it have been easier to simply open up the flue sheet holes to the appropriate diameter, rather than "building a machine" to swedge the flues down in diameter?

Absolutely not, as reduction of the sheet material between all those holes, would have set up undue stresses. The only proper way was to re-swedge the rear ends of the flues in order for them to PROPERLY fit the existing tube sheet holes.

The bigger question is, as I stated above, why didn't the flue/tube supplier make the ends to the CORRECT size?

Side question or questions. How many workers does Ed have under him right now compared to what Steve had? Plus how many combined years of experience did the former crew vs the current crew have/had? Also are there any outside contractors doing work on 844 right now?

I know the answers to my questions might not be public knowledge but I figured Hot Water would have some insight.![]()

jmiller320 posted:I know how everyone enjoys these updates and they may not subscribe to Facebook.

Some of us (me included) enjoy them. Others, I worry about them having a stroke everytime anything comes out of Cheyenne... That, and some want to pull out the pitchforks and torches and re-enact the ending of the movie "Frankenstein" every time this comes up.

Thanks for posting this as you're right that not every is in the Facebook cult.

Hot Water posted:The bigger question is, as I stated above, why didn't the flue/tube supplier make the ends to the CORRECT size?

Thanks Hot. I think this answers my question: The tube supplier should have made the diameter smaller upon manufacture.

Yes, I can see this being a major screw-up on someone's part.