Finished fastening the railroad signs to the fascia

RSJB18 posted:

Nice Bob! That sure turned out looking sharp! Great work!![]()

beardog posted:the single life is nice, no wife, happy life

agreed... ![]()

Attachments

Thanks Mike.

Made a bit more progress this week with the elevated platform that will soon become the base for Mount Krog and the Krog Tunnels. The section is cut from 1/2" plywood and supported by 7.5" 2x4s and 1x4s. The elevated section can easily hold my weight - I plan on further testing the tensile strength of it by consuming more beers this weekend

Any recommendations or suggestions as to if and how I should secure the supports to the underlying table/homasote? I'm thinking either white glue under the columns or just let gravity do it's thing. I don't really want to run screws up from the bottom as it'll affect the sound-deadening capabilities of the homasote. If the consensus is to run screws up from under the table, I'll likely only do a few columns, just to ensure that the platform stays in place.

how bout hot glue on a few columns?

Or some contractor glue for HD or Lowes ... All that looks great Mat! And my mind got to clicking. Has anyone tried advantech sub floor instead of plywood? That stuff is TOUGH!!!!

Jim

mike g. posted:RSJB18 posted:Nice Bob! That sure turned out looking sharp! Great work!

That turned out great!!! Some really good ideas your posting Bob!

Jim

carsntrains posted:mike g. posted:RSJB18 posted:Nice Bob! That sure turned out looking sharp! Great work!

That turned out great!!! Some really good ideas your posting Bob!

Jim

Thanks Jim- I've been making it up as I go. Imagine what I could do with proper planning...![]()

645 posted:beardog posted:the single life is nice, no wife, happy life

Uh - Mitch is NOT single! Did you forget about Norma Bates the Kitteh who lives with him?

Ummm- cats don't live with us, they permit us to live with them. ![]()

Bob, the overhead bridge line is looking better and better!!!

Thanks Mark. Still a work in progress but I am happy with how its going. My goal is to eventually build a station platform between the siding and the main line as a focal point.

Bob

Bob, your project is coming along great. I like the looks of the sides. Well done. This morning the first thing I did was open my package that came yesterday. I got it of EBAY. The price was right and I didn't have that road name. The only thing I have to do is mount wheels on the trailer. I have some undecorated trailers coming which I could take a set off of one of those or just hit some train shows and see what may be out there that would work. And of course next month I may find them at York. After that I worked on the last sections of the fence, all done with that little project. I'm just waiting for the glue to dry. I'll drill a hole for the wire from the sound shed and then vacuum up the area. This afternoon I'll probably start back up on track work. Pics...............Paul

Attachments

Paul, the trailer on flat car looks great even missing the wheels. It's nice you have a donor vehicle on the way!! The fence looks great too! It is a much more heavy duty look than a simple chain link fence.

Thanks Paul.

The scrap yard fence looks great. Don't know how you feel about weathering but some rusty spots on it would really look sharp. Nice TOFC too.

Paul, the fence turned out really nice! Its going to be a wonderful addition to your layout!![]()

Soldered new wire leads, then I decided to solder some more wire leads, then I came back and soldered some more. Almost done, yea right.

Jushavnfun posted:Soldered new wire leads, then I decided to solder some more wire leads, then I came back and soldered some more. Almost done, yea right.

Wiring is my the part of layout building I do not like. Soldering is the worst part for me. Who would have guessed it as I was trained as an electronics technician! I'm glad I haven't had to do any of it at work the last few years! ![]()

I soldered thousands and thousands of solder joints when I was a tech at ATT.

Now that is am retired, I use wire nuts.

beardog posted:I soldered thousands and thousands of solder joints when I was a tech at ATT.

Now that is am retired, I use wire nuts.

I like the way you talk!! Terminal blocks work for me too.

645 posted:beardog posted:the single life is nice, no wife, happy life

Uh - Mitch is NOT single! Did you forget about Norma Bates the Kitteh who lives with him?

And don't forget Sylvia Siamese! ![]()

Mitch

Actually tho, when I was 7 or 8 building my first layout I soldered all the

wiring, made insulated track sections for the signals, built my own switches. Even

wound my own magnets for uncouplers.

Amazing what you learn to do when you are poor.

645 posted:Adriatic posted:BANDOB posted:After 5 hours of running on Saturday, some equipment went to the shops on Sunday for COT&S.

What exactly does COT&S mean? I struck out on a search in the acronym tread and online both. Here in Detroit it's a Coalition of Temporary Shelter... search engines think I want Army cots for napping

Did you try "railroad COT&S" as search keywords? I got multiple immediate hits.

COT&S = Clean, Oil, Test & Stencil. (Applies to air brake rework.)

Thank you. Not exactly, I used cots first and the search engine threw out the other terms. Boolean terms get tossed by the search engines now and I can't figure out how to force them to anymore. My searches were way more productive with them, but that doesn't sell me crap I guess.

Any idea what stenciling is for? Shoe dimension? Shoe tracking?

Thanks Bob on that idea. I was toying with that but have to find some pictures of a rusted fence. I have a bottle of rust paint.Had to run out to Sam's Club for some house items but I had gotten a flyer that had the LED shop lights on sale. 7.00 dollars off each one. So I picked up two more for the basement. Finishing off the fence I drilled a hole for the wire of the sound shed and vacuumed up the whole area. I didn't like the color of the base so I had some aged concrete paint left and I put one coat on. Think it made it look better. Then I got out some fine black ballast and started laying in a road through the gate over to the shed. I laid down some strips of Balsa wood for a track crossing in the yard. Later I'll start gluing the road down. Pics...................Paul

Attachments

Adriatic posted:Any idea what stenciling is for? Shoe dimension? Shoe tracking?

Date the service was performed, I imagine.

Mitch

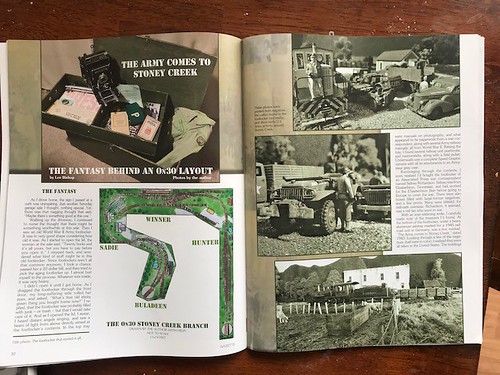

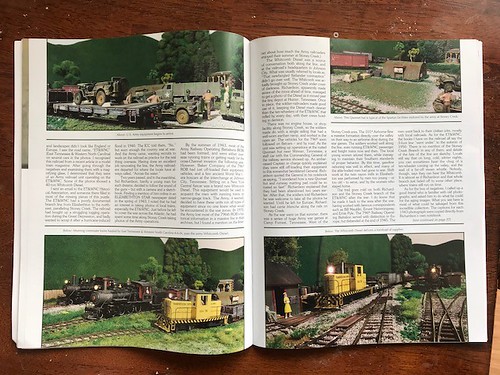

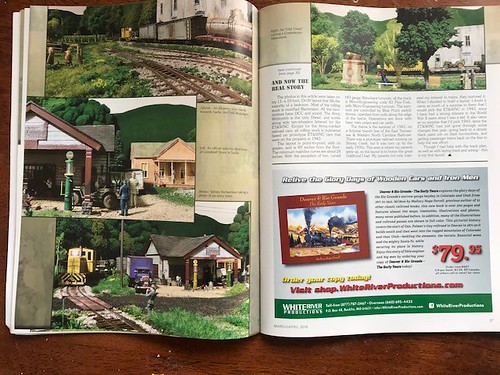

I know it's probably a Faux pas to do this, but I got my layout in an article in a competing* magazine, Narrow Gauge and Shortline Gazette, in the March/April 2018 issue:

*I don't think this is competition as such, as OGR certainly is focused toward a very different aspect of the hobby...

Congrats Lee. I'm sure the publishers are ok with supporting the hobby.

Working on weathering 2 freight cars, trying some new techniques blending alcohol washes with pastel powders. At the same time, I am weathering weathering Korber Joes Pickle Factory, which I just bought from a fellow OGR forum member... Evaluating whether to put Joes together as a 6 story backdrop building, or the more conventional 39 inch long - 3 story flat....

Attachments

Wonderful job especially on the freight cars. Who is the manufacturer of the outside brased gondola? I've been looking for one of these for a while now.

Thanks;

Mike

Thanks Mike, It's an Atlas O Item 8802, Atlas 40 ft. Composite Gondola NYC

Thanks Chris .Keep up excellent modeling!

Mike

p51 posted:I know it's probably a Faux pas to do this, but I got my layout in an article in a competing* magazine, Narrow Gauge and Shortline Gazette, in the March/April 2018 issue:

*I don't think this is competition as such, as OGR certainly is focused toward a very different aspect of the hobby...

Congrats Lee, well deserved!

My saga continues as I work every day cleaning out the living space where I intend to live and have a layout. The previous occupant (deceased) was a hoarder and lived like a pig but I now have the bedroom cleaned up and a nice bath. A new kitchen is being installed and almost finished. Last but not least, the living room where my layout will be is almost clean of trash and dirt. So there has been a lot of drama and progress. Right now it appears the layout will be about 9 ft wide and 15 ft long. The modules will be approximately 2 ft wide on the long sides and 4 ft wide on the ends. They will be built like my old layout- 1x4 frames and legs with cross bracing on the top covered with Homosote covered by green indoor/outdoor carpet. Using clean O gauge tubular track from the previous layout. There will be 3 loops of track, the outer one O with 072 curves, the second standard gauge with 054 curves and the inner O gauge with 054 curves. No switches, conventional control and my tinplate and other buildings. Main goal right now is to run trains. Possibly tomorrow I will start to bring the boxes out of the shed where stored. It has been almost a year- way too long and I am excited and impatient.

Attachments

beardog posted: I soldered thousands and thousands of solder joints when I was a tech at ATT.Now that is am retired, I use wire nuts.

Too many failed crimps before I started tech to ever give up soldering. I tend to spend more time inspecting crimps than it takes to heat an iron, so anything more than one or two and the iron gets hot. I do get that it is too much like work though. My pet peeve is lack of slack in wire length, or even worse, ribbon cable... or gambling on wire colors. I've even seen 5 wire codes in one machine, three countries standards and change in ones standards ![]()

Thanks Mitch; makes sense.

Well alright Jim! ![]()

Great work on the flood recovery, Gandy Dancer.

I have question. I see you have a white 6112 that is boxed. I believe it was only included in the set with the 44ton 625. Did it ever come boxed?

Thanks;

Mike

Mike welkie posted:Great work on the flood recovery, Gandy Dancer.

I have question. I see you have a white 6112 that is boxed. I believe it was only included in the set with the 44ton 625. Did it ever come boxed?

Thanks;

Mike

Great notice. The 6112 is in a repro window box!

Thanks for the quick reply. The repro boxes not only enhance your display but also afford protection for the rolling stock.

Mike