@mike g. Love that!!! I am a big BNSF fan. Cannot wait for MTH WTIU comes so I can fully use my #5738 I watch Railfan Dan and 7Idea productions youtube videos, every night before bed! Lol! The views of those lines out west are amazing.

@mike g. @DoubleDAZ @Mark Boyce a little operations before bed 😁

Hey guys, trying to troubleshoot my setup. As you guys can see from my videos the Pennsy goes the opposite way just fine. Running the Mikado opposite direction, it keeps either partly derailing (front 2 wheels come off slightly randomly and especially when it goes into the inner loop. I got it to stop by opening the o45 switch that leads to the new house. But when I reverse it on that spur to connect to the cars in the house the cab light starts to blink and the loco won't move. It isnthe strangest thing. I have never had a derailment with this locomotive going in the direction of all its videos. Since turning it around it can barely make a loop around both inner and outer. As a matter of fact, it has not made 1 full revolution outside then inside. I am confused. Any insights would be much appreciated! @Mark Boyce @DoubleDAZ @mike g.

Ken, does it derail at the same spot each time? Does it happen at one of your switches? The pilot ‘front’ wheels on a steam engine can be fickle, I think because they ‘float’ there is no weight over them.

Are you saying that when you run the Mikado counter-clockwise, it runs full inner and outer loops without derailing, but when you run it clockwise, the front wheels randomly derail on both loops? Does that happen at the switches or anywhere? If it happens at the switches, the wheels are hitting the points in the opposite direction, so maybe they aren’t seating properly for that direction? And you say you got that to stop by simply opening the O-45 switch toward the spur? That would suggest an electrical problem of some sort if the derailing happens at the switches, but I can’t think of how.

Then you’re saying that when you back it through the inner O-45 switch on the spur, it stops at some point? That also suggests electrical. What happens if you pull in instead of backing in?

Dave, thank you for stating more in depth what I asked Ken a little earlier. I was on the phone in the car stopped in a parking lot in a downpour. ![]()

So, yes what I figured out to @Mark Boyce point the front wheels are fickle, so I opened the switch and it went fine, but then when i backed in to the spur to the houses, it wont go forward, the cab light starts to blink. This only happens on the steam...the diesel's all run smoothly. I am thinking about @Mark Boyce point that there is a little dip and the front wheels may not be touching properly? I will do a video to better show. I will do the diesel, as a matter of fact, i have plenty of videos of the diesel, but i will attach one and the Mikado attempting to make the same moves. It may help troubleshoot. I will run the steam both loops one way and both loops reverse direction (not backwards). Standby, gents.

I think you are on the right track, Ken! Bad pun, I know! ![]() If I slowly run a steam engine over certain areas of my track, I can see the pilot wheels appear to lift up a bit, but not off the track. At faster speeds, they can derail. Switches can cause the problem too. I am the first to admit my track is vertically wavy, though folks who have watched my videos say I have smooth track.

If I slowly run a steam engine over certain areas of my track, I can see the pilot wheels appear to lift up a bit, but not off the track. At faster speeds, they can derail. Switches can cause the problem too. I am the first to admit my track is vertically wavy, though folks who have watched my videos say I have smooth track. ![]()

Mark, I was composing and didn’t see your post until after. Nice to see we’re both thinking the same, you have more experience.

https://youtu.be/CjgqftpiE-0 from few days ago Diesel

https://youtu.be/zd8-alT8bDs Mikado today.

The cab did not blink in this video like it did yesterday, but the loco did not move as you can see. It is still making noise, which the speaker is in tender, so the loco itself is not moving, which means @Mark Boyce is probably on to something. There is not much weight in the front and the loco is probably back heavy, this is an incline. I think trying to fix that little dip might be the answer? Thoughts?

@Mark Boyce I always worried about my track being level, but knew that it is impossible to do on a moving platform, so I do not worry about it. I have since been watching 1000's of real world track and they are not even remotely level and the trains make the same movements as mine. The key is knowing the spots and watching speeds in those spots. The interesting part is the Mikado has never derailed going to other way and holds the rails really well, inner and outer. It is a very heavy locomotive, which i think is the problem with running it the opposite direction as the grade is steep on that side of the inner oval. If it is running the other way, the grade is much more even and longer uphill, the switch side (of grade) drops faster, so running that way is causing the problem for a steam with tender. It does not happen to the single body diesels.

@DoubleDAZ posted:Mark, I was composing and didn’t see your post until after. Nice to see we’re both thinking the same, you have more experience.

Dave, I have more experience with a good plan, but not the best execution. That is, I really struggle with construction of smooth roadbed and track and always have in O, HO, and N scales. Back 35 years ago, I had the same problems with N scale. I thought with larger scales, somehow those issues would go away. Not so. I have proved it. However, I am not alone by any means. A couple of Saturdays ago, I went to a train show with lots of modular layouts. Over and over I observed the same kinds of problems I have.

@Dntbsillynow posted:@Mark Boyce I always worried about my track being level, but knew that it is impossible to do on a moving platform, so I do not worry about it. I have since been watching 1000's of real world track and they are not even remotely level and the trains make the same movements as mine. The key is knowing the spots and watching speeds in those spots. The interesting part is the Mikado has never derailed going to other way and holds the rails really well, inner and outer. It is a very heavy locomotive, which i think is the problem with running it the opposite direction as the grade is steep on that side of the inner oval. If it is running the other way, the grade is much more even and longer uphill, the switch side (of grade) drops faster, so running that way is causing the problem for a steam with tender. It does not happen to the single body diesels.

Ken, I watched the video and can't tell what is going on. Your last post states the same problems I have. Diesels can be run much more reliably. One question I just thought of. Does your Mikado have pickup rollers on the tender? I have one engine that doesn't. Also, When one of my engines struggles with an upgrade, the drivers usually start to spin then it stops. My grades are much steeper than yours so spinning may not happen.

@Mark Boyce no spinning and my tender does have pickup rollers. I think this is one of those, it is what it is. The Mikado will have to run as it has and i wont be able to use the house for it. Not a biggie...honestly. i just wanted to start it in the house and smoke it up, like i do in the mountain and have it leave the house...a little drama. ![]() Sucks that the Mikado which has been 100% successful at all speeds cannot run the opposite way. I do like to open it up from time to time as the smoke really pours out at high speed to low speed. It does not get super white at low speeds. A couple times around at max speed really gets the smoke white. I cannot replicate that at low or med speed. The diesel's do not smoke like the steam, although my BNSF seems to smoke way better than all the other diesel's. In real life a well maintained diesel just has heat flume, that is what my other diesels do. The #5738 smokes almost like the Mikado...lol!

Sucks that the Mikado which has been 100% successful at all speeds cannot run the opposite way. I do like to open it up from time to time as the smoke really pours out at high speed to low speed. It does not get super white at low speeds. A couple times around at max speed really gets the smoke white. I cannot replicate that at low or med speed. The diesel's do not smoke like the steam, although my BNSF seems to smoke way better than all the other diesel's. In real life a well maintained diesel just has heat flume, that is what my other diesels do. The #5738 smokes almost like the Mikado...lol!

The diesels will be the stars of the house...all good! Appreciate all the help, gents! Happy modeling!

On another note, doing the center different. I liked the foam concrete pads and now I know I can do them...lol! But scaling that within the open space won't work or be enjoyable, lol! I found out that there are many paints that simulate different textures like sand, dirt, mud, and asphalt. So, i am going with concrete base paint and will follow-up with dirt, grass, asphalt, etc

@DoubleDAZ @Mark Boyce @mike g. Hi guys! Another question maybe someone can help. I had a cheap signal that I hooked up to my switch and it worked sometimes. So, I decided to get an Atlas 21st century 6911 signal and of course I already ballast, etc but I saw online that just cutting the track will also create an isolation and add a wire right before the end of the 2nd cut as a trigger for the module. I followed all the directions, yet all I get is a solid red no matter where the locomotive is on the tracks. I am wondering if I did not need to do what Eric from Eric's trains said to do which is connecting the ground of the two power sources as he uses seperate power for track and accessories. I did run a negative wire between the two accessories and outer line power blocks. Should I remove that since the power is coming from 1 transformer (albeit different parts of the transformer) thoughts?

Another video of some newest updates. Asphalt ![]()

Your concrete color looks nice as do the details.

Ken, I don't have any suggestions on the electrical questions. I do think all your problems are being caused by Yoda messing with you! ![]()

You may want to start new topics in the appropriate sections of the forum. I think you would get more visibility and more folks coming in with helpful ideas if you had descriptive titles for each new post.

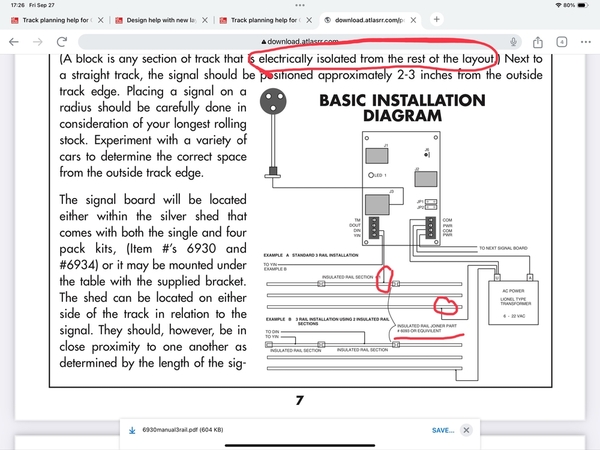

Ken, I see the cuts in all 3 rails, but aren't those rail joiners metal? If they are, they're conducting electricity.

I'm still bummed about the Mikado. If you followed the design, the inner oval should all be the same elevation. The grades go from the outer oval inside the tunnel to the crossovers and they are only 3%, something the Mikado should have no problem climbing, regardless of direction. I can see the front wheels derailing if the points in one direction are slightly off or the wheels are out of alignment or something.

As far as the inner O-45 switch goes, is there an incline from the switch to the house? It looked like I saw the engine dip or tilt. Is the curve past the switch fully supported?

@DoubleDAZ the rail joiners are metal, but according to Eric from Eric's trains, you must cut the rails in this manner in the event you are adding signals after ballasting, etc. The negative from the opposite outer rail carries the ground. The cuts isolate that section of track. If there is a switch in between the beginning and end of the isolated track, you have to cut in front of and back of switch - Atlas says that part, but they say it with plastic joiners, which I cannot add. As far as the switch, the grade is not exactly the way it should be and the house needed me to have slightly higher track to work properly. I needed to have the house sit on the wood ties. In order to do that I used 2 strrips of the foam bed, instead of 1. There is a slight dip after the switch as the spur was flat coming from switch prior. Yes, I am sure that is the problem associated with this issue. However, the diesels do not have this issue, I think it is that slight dip with the design of a steam is causing the problem. I am not terribly worried about that anymore. Remember, I am a rank amateur and am sure I did not get it all perfectly. 🥴

Ken, if you’re ok, I’m ok, just wanted to try to find an explanation the seemed to fit the situation. I’m pretty confident the track and style of engine are the problem. I think you’ve done a fine job and if you had to do it over, I’m sure you’d be able to eliminate the problem.

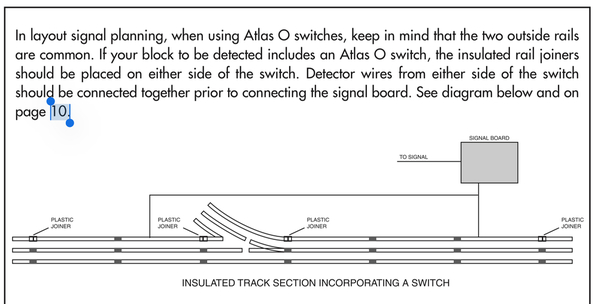

As far as the cuts, I thought the idea was to isolate the track at the cut. Seems to me you have to cut through the joiners too, not just the track, since you’re not really isolating the connection, electricity is still flowing across the tracks through the joiner. Plastic joiners do just that, they completely isolate the electricity. I couldn’t find that signal on the Atlas site to look at the instructions.

It is on their site, i believe it is the 2nd one down under signals. I did not cut the joiners. I cut spots by themselves and between ties, as instructed. All joiners are still in place. I am in NYC on set filming a TV show. I will take a video tomorrow. It is the same information as PRR. The booklet actually is for both the PRR and color position light. Why, i have no idea...lol! I have been playing phone tag with Bill from Atlas corporate for 3 days 🥴 I have gone to the internets for support, lol. I initially cut 2 spots after the switch, but red the directions wrong and it said at least 30" of track. That meant going farther to the right and that made no sense as that is the 1st wall side of the layout and no one would see the signal. The best location is where it is for practicality and function. So,I then cut right before the switch and right before the bend (where 2nd pond is) According to atlas, in the case of a switch in between the block you are isolating, there needs to be 2 wires spliced together and that splice run to din slot.

@DoubleDAZ here is Eric's video. https://youtu.be/6bUWymTNBHo?si=I3YNf1xgV0GNFC_q

but *read* directions wrong..... needs to have track length of at least 3 - 10" sections....

So, according to Atlas diagram of blocks with switches inside, there should be 4 joiners/cuts....1 to start the block, 1 to end the block and 1 on either side of the switch. Then a negative line at end and beginning of block, splice together and that running to din port of module.

@DoubleDAZ this one is it in 2RL, it appears they lump the PRR with the 3rl...

Attachments

Sorry, not trying to be stubborn. My understanding of a single signal setup is that it’ll cycle through a timed sequence of red-yellow-green when a train enters the "electronically" isolated block. That means either cut "all the way through" or insulated with a plastic joiner. If you look at the photo, it’s shows power to the outside rail opposite the isolated (signal) rails. It also shows the signal rail is cut all the way through and they recommend bridging the gap with an insulated (plastic) joiner. Power goes from the transformer to the outside rail. A wire goes from the signal to the isolated rail on the non-powered side of the isolated section. When an engine hits that section, power is transferred via the wheels to the signal rail triggering the sequence. If the signal rail is connected with metal joiners, the sequence is not triggered because the signal is constantly powered through the metal joiners.

Now, I’ll admit I might be wrong. I’m not there looking at the instructions you are, but I know for sure that the metal joiners there bridge the gap you cut resulting in it still being connected electronically. If you had set this up while laying track, you would have added the insulated joiners where your cuts are and that section would have been electronically isolated. As it is now, it is not. I would think someone else reading this could confirm or refute what I’m saying. If no one knows or noticed that you have metal joiners still connected, that might explain why no one has come up with a solution. Did you start a thread in the Electrical Forum?

Attachments

I just watched some of Eric's Part 1 where he puts the test tracks together using the small “insulated" joiners on one rail to isolate the block electronically. The only reason they talk about length is because they assume there’s going to be more than one signal, 1 at each end. Since you only have one, you only need a short block to trigger it. 3 10" tracks is 30", so I don’t know that you really read things wrong. In there he also says you only need one track.

At about the 40 minute point in Part 2, he shows cutting the signal rail all the way through. He then draws the diagram showing the power feed to the other rail and the signal feed to the isolated block. He also shows how to hook up a spur so they both trigger at the same time, something you could do with the O-45 switch to the house.

Cut all the way through and make sure to slip a piece of styrene in the gap so it ensures it is isolated. I knew better but didn’t put a bit of styrene in the gap. Rail slid against the other end quickly, and bridged the gap. I don’t know if that is your problem. I may have missed something.

@DoubleDAZ I did cut all the way through. As far as reading wrong, I meant that initially I only isolated about 20" of track. To get to 30" + i had to bring the large switch area into the mix. According to Atlas instructions, switches must be setup differently if they fall within thr isolated block and they do. I must do 4 cuts or plastic joiners. I did that. The track is cut fully and I will measure, but it is at least an 1/8 - 1/4. I made sure of that. I will make a video and new thread to see if someone can direct me on what I am doing wrong. @Mark Boyce they styrene could be the missing piece. If the current is still jumping a 1/8" then the styrene may solve all this.

Well 1/8” is a quite large air gap. I don’t see that is the problem

@DoubleDAZ @Mark Boyce does the soldered wire need to be on the opposite negative rail, not the broken side? Is that the small oversight I am missing? Is that the break point? 🤔🤔🤔🤔

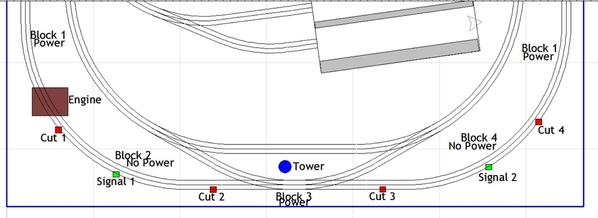

Okay, Ken, correct me if I'm wrong. If I understood the video, you have 4 cuts where I have the red squares in the photo.

The 1st is around the left side curve, the 2nd is before the switches, the 3rd is after the switches and the 4th is around the right side curve.

All the cuts are on the outside track and go all the way through. In the install manual and Eric's videos, the cuts are all on the inside rail. AFAIK, that shouldn't make a difference.

Anyway, I couldn't tell what wires you were connecting or where you were connecting them to. The 1st one is connected somewhere behind the elevated walkway, but is it between Cut 1 and Cut 2? The 2nd one was around the right curve, but is it between Cut 3 and Cut 4?

I also couldn't tell where both wires came from. I only saw 1 wire connected to the Din plug on the circuit board and that's the wire that should be connected to the Signal 1 position in the photo. When the engine moves into the first block, it triggers the signal. The signal then cycles through red-yellow-green.

If the wire from the Din plug is split, then the 2nd wire should be connected to the Signal 2 position in the photo.

Is this how you have it?

Now, the engine runs through all blocks before the wires are attached, so we know there's power to the inside rail. When you connect the wires, the problem starts, so we know the cuts to the outside rail are cutting power because the signal changes colors showing there is an engine in the block.

I have the brown engine in Block 1 and the signal is green. When the brown engine moves to Signal 1 in Block 2, it triggers the signal and that starts the red-yellow-green sequence. I assume the signal stays red until the engine moves to Block 3 where it changes to yellow, then green again. However, the length of Block 3 is pretty short and I don't know if the sequence can complete before the engine moves on to Signal 2 in Block 4.

With both wires connected, what happens if you stop the engine in Block 2? Does the light turn red and stay red?

Then what happens if you stop the engine in Block 3? Does the light cycle through yellow and green?

And then what happens if you stop the engine on Block 4? Does the light turn red again and stay red?

What happens when you move on to block 1 again? Does the light cycle through yellow and green, then stay green?

Attachments

@Dntbsillynow posted:@DoubleDAZ @Mark Boyce does the soldered wire need to be on the opposite negative rail, not the broken side? Is that the small oversight I am missing? Is that the break point? 🤔🤔🤔🤔

Not sure what you mean by "soldered wire". The wire from the Din plug on the circuit board goes between the cuts on the broken side. If that wire is split, then each wire goes between the cuts on both sides of the switches. That way the signal gets triggered before the switches from either direction.

Attachments

That is exactly how it is setup. Per these instructions that came with the signal. In order for the din wire to be connected to the rail, it needs to be soldered.

Hi Dave, if I am seeing this correct and your marks for cut 2 & 3 are where you put them. I can see one problem, if the switch is made to either bring an engine out to the outer loop or the other way from the outer loop it's going to say that the block is always full. As it is closing the circuit. The outside rails on the switches are connected to the outside rails of the outside loop making a circuit .

It is hard to tell, but a good test would to set both switch's to keep inside train inside and the one on the out.

If that doesn't work I would think about cutting the outside rail on both switches between the inside and outside loops.

Just my thoughts.

Mike

@DoubleDAZ my only difference is I did the cuts on opposite rail. I cut outside common, instead of inside common. According to Eric he does inside because it hides the wires. I have not read anything that says it has to be inside common. I originally did a section outside of switch area. It had sake result as current setup with the 4 cuts. Which lends me to think it does not matter

I just got on and I think Mike has one excellent point. An engine can bridge between two blocks. I have never fooled with this before. Eric did a great job as always on his video, but doing it yourself can usually open a can of worms that the instructor left in the bait refrigerator. ![]()

@Dntbsillynow posted:@DoubleDAZ my only difference is I did the cuts on opposite rail. I cut outside common, instead of inside common. According to Eric he does inside because it hides the wires. I have not read anything that says it has to be inside common. I originally did a section outside of switch area. It had sake result as current setup with the 4 cuts. Which lends me to think it does not matter

I tend to agree until it comes time to connect the inner tracks to the signal. You probably won’t do that, but I’m not sure how that would be wired. The inner tracks would be wired the same as the outer tracks, but I don’t know how to wire things so that when a switch gets thrown, it triggers the signal.

@DoubleDAZ my original signal was setup to match whether switch was thrown. I went away from that because the actual signal was cheap and sometimes worked. There is a different board for that process, which is still under layout. I decided to just go with a block signal as it makes more sense and will eventually add dwarf signals for switch operations. Right now I am just focusing on that block setup of identifying a train on that stretch of track.

Good to know you already have the other circuit board, but I completely understand the need to get this working before attempting more.