UPP #2066 HUMP Update

I received a very beautiful laser cut and labeled box from Alan containing the pieces/parts of the Hump.

When I first saw this, I was totally surprised, floored even.

Inside the box was a laser cut insert containing the cutouts for the side vents and fans.

The fans are with the main parts of the hump which is underneath.

Remove the insert and this is what you see. Well, what you would have seen is the side vents in the body, and the 3 main parts of the body inserted in the insert.

As I said, I was very impressed with the box! There was NO WAY the USPS would have destroyed the parts without destroying the box.

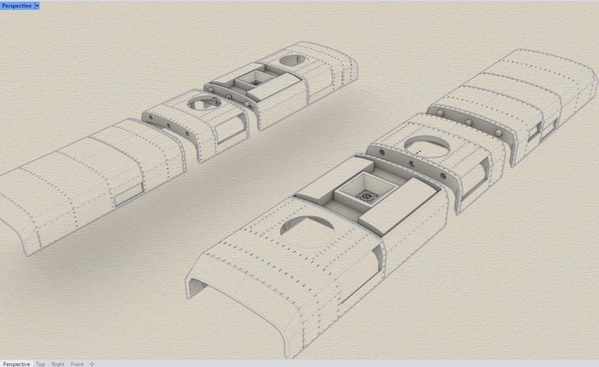

So moving on. After close examination of all the parts, I couldn't wait to start trimming and cleaning up the hump. I glued the 3 sections together and allowed them to dry before doing any manhandling. I then placed the hump on top of the car to get some sort of perspective of what I had. I'm totally liking what Alan has pulled off. This is going to be sooooo cool when it's finished.

This afternoon I sanded the ends to get a better fit to the roof. I still have some forming and fitting to do. But with any first time project, there's a huge learning curve that goes into this. I will be detailing the build of the HUMP so others will have the opportunity to see how I put this car together, if Alan is so inclined to put this out for others.

I'd like to say...Alan and I have sent LOTS of emails back and forth and it's still a work in progress. Alan has been very accommodating to my OCD. This is going to be a one off, at least for me and I'd like it to be as Prototypical as possible.

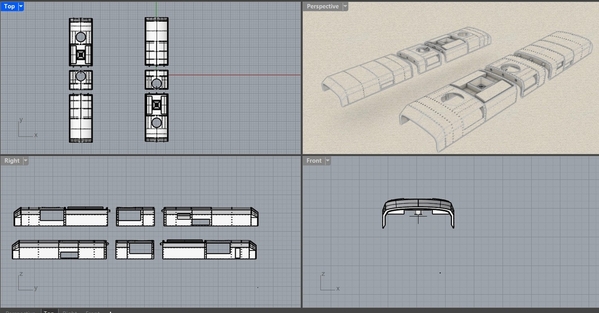

Alan does awesome 3D work as many of you folks know. I am completely and totally impressed with this "Hump". It was well worth the wait!

I just can't say this enough, Thank You Alan!

Until next time...Stay tuned, More to follow throughout the winter.