Originally Posted by suzukovich:

It got me too. Your thinking Lees, Grants and Shermans. I thinking Abrams and Pattons( M60 series ) It just gives away our mind set.

The funny thing is I only served in a heavy mech units in my Army career and was around Abrams, Bradleys, and the like every single day. I was also rated to drive everything in our Brigade as a Master Driver officer in one Batt I was in. Heck, I even drag-raced a M-1A1 against a shop officer in a Bradley in a motor pool, and I left him in the dust (one of the many things I never mentioned to people until I left active duty).

But when you mention tanks, I still think of Stuarts and Shermans. I've always been a huge history fan more so than anything else.

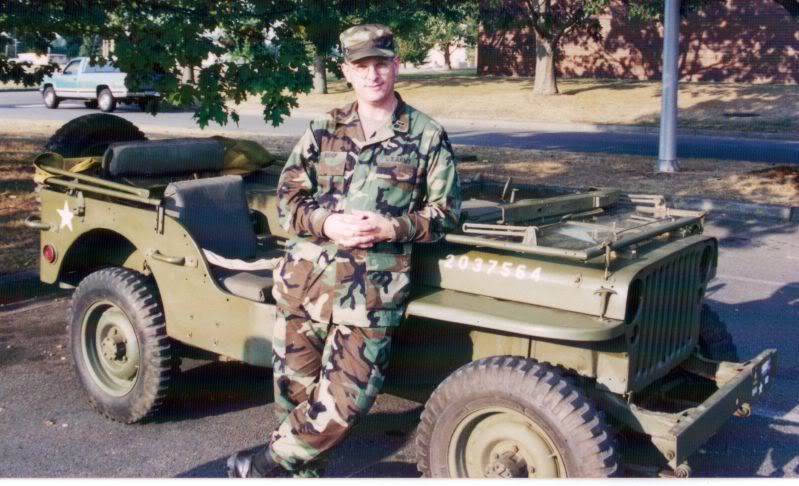

See what an odd image this made when I'd drive my 1944 Willys MB Jeep onto the post!